2026 Top Rigid Flex Technology Trends You Need to Know?

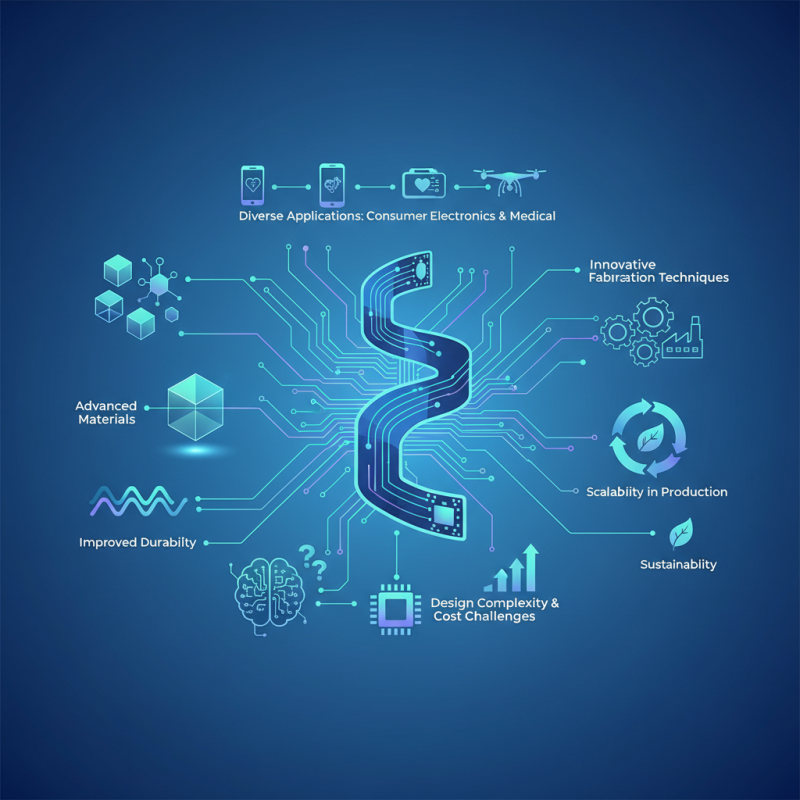

As we approach 2026, the landscape of rigid flex technology is rapidly evolving. Rigid flex circuits combine the best of both worlds: flexibility and durability. This unique characteristic makes them suitable for various industries. From consumer electronics to medical devices, they play a crucial role.

However, the advancements come with challenges. Manufacturers grapple with design complexities and production costs. Innovations in materials and fabrication techniques are emerging. These developments aim to enhance efficiency and performance. Yet, questions linger about sustainability and scalability in production.

In this exploration of rigid flex technology trends, we will delve into key innovations. We will look at how they impact the industry. Understanding these aspects will provide valuable insights into the future of rigid flex circuits. Is your business ready to adapt to these changes?

2026 Overview of Rigid Flex Technology Innovations

Rigid flex technology is evolving rapidly, with exciting innovations on the horizon for 2026. This hybrid technology combines the benefits of rigid and flexible printed circuit boards. One notable trend is the integration of advanced materials. These materials will improve durability and flexibility while reducing weight. The deployment in consumer electronics is likely to increase, making devices thinner and lighter.

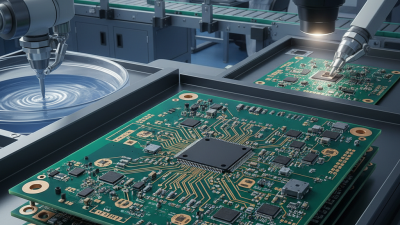

Another key development is in manufacturing techniques. Automated processes are becoming more prevalent. This shift may lower production costs and enhance precision. Enhancements in design software are also vital. Designers will have more tools to create intricate layouts. However, the complexity of these designs can be a double-edged sword; more detail could lead to longer production times.

Sustainability remains a critical focus. The push for eco-friendly materials will continue to grow. Innovations may lead to recyclable components becoming standard. Yet, challenges persist in balancing performance and sustainability. As companies strive to meet these dual demands, they must reflect on their production methods and environmental impact. This ongoing evolution in rigid flex technology promises to reshape industries dramatically.

Key Developments in Rigid Flex Materials and Manufacturing

Rigid flex technology is evolving rapidly. This development combines the benefits of flexible and rigid substrates. It's increasingly used in various industries. Advancements in materials drive enhanced reliability and functionality. Manufacturers are optimizing production methods for efficiency.

Key developments focus on new materials. Innovations in polyimide and other polymers improve durability. These materials allow for thinner designs and lighter weight. This is crucial for consumer electronics and automotive applications. The ability to withstand heat and mechanical stress is vital.

Tip: Consider how these materials can reduce overall product costs. Efficient manufacturing processes often lead to faster turnarounds. However, challenges remain. Balancing customization and mass production is tricky. Innovations bring opportunities, yet require careful planning.

As more companies adopt this technology, awareness is essential. Understanding its capabilities can aid in smarter product design. Keep an eye on trends to stay ahead. Embracing change might demand adjustments. Preparing for these shifts is key to staying competitive.

2026 Top Rigid Flex Technology Trends

Impact of Rigid Flex Technology on Consumer Electronics

Rigid flex technology is reshaping the landscape of consumer electronics. This innovation merges flexible and rigid circuits, allowing for more compact designs. According to a recent market report, the global rigid flex circuit market is expected to grow at a CAGR of 8.5% from 2021 to 2026. Such growth indicates increasing demand in industries like medical devices, automotive, and smartphones.

The impact on consumer electronics is profound. Devices become thinner and lighter, enhancing portability. Wearable technology, for example, benefits significantly from this advancement. A study noted that 75% of major tech companies are investing in rigid flex solutions for wearables. However, challenges persist, including higher production costs and complex manufacturing processes. Companies must rethink their strategies to integrate these circuits effectively.

Moreover, the need for sustainability in electronics adds another layer of complexity. While rigid flex technology promises innovation, it’s essential to consider the environmental impact of materials used. A report highlights that over 30% of electronic waste stems from outdated manufacturing practices. As the consumer electronics sector evolves, balancing innovation and sustainability will be crucial.

Sustainability Trends in Rigid Flex Circuitry

Sustainability is becoming crucial in the rigid flex circuitry industry. A recent report highlighted that the demand for eco-friendly materials in electronics is growing by 35% annually. Companies are looking for ways to minimize their environmental impact. This includes using recyclable substrates and reducing harmful substances.

Rigid flex circuits often feature multilayer designs. However, the materials used in production have significant environmental footprints. For instance, traditional copper plating can lead to toxic waste. Shifting to sustainable materials can mitigate this issue. A report from a leading research institution emphasizes the need for alternative conductive materials. These materials can reduce pollution without sacrificing performance.

Tips: Consider using biodegradable lamination materials. When selecting components, prioritize suppliers with green certifications. Regularly assess your supply chain for sustainability compliance. Remember, innovation may require changing long-established practices. Sometimes, the path to sustainability involves difficult choices. Embracing eco-friendly solutions can lead to market advantages in the long term.

Future Prospects for Rigid Flex Applications in Diverse Industries

The landscape of rigid flex technology is evolving rapidly across various industries. This hybrid solution combines flexibility and durability. Applications range from consumer electronics to automotive sectors. Each field benefits uniquely from this technology. For example, smartphones use rigid flex circuits to save space while maintaining performance.

Tips: Evaluate your design needs carefully. Rigid flex may not be the answer for every project. Prototype early to avoid costly mistakes.

In medical devices, rigid flex circuits offer thin profiles with complex functionality. They ensure reliability in critical applications. However, the production process can be tricky. Quality control is paramount. Companies must address potential failures proactively.

Tips: Implement robust testing procedures. A small error can lead to significant issues later. Stay updated on manufacturing advancements for better outcomes.

| Trend Category | Description | Potential Applications | Expected Impact |

|---|---|---|---|

| Miniaturization | Increased demand for smaller electronic components driving innovation in rigid flex technology. | Wearable devices, medical implants, and compact consumer electronics. | Improves portability and convenience for users. |

| Sustainability | Focus on eco-friendly materials and processes to minimize environmental impact. | Green tech products, recycling processes in electronics. | Reduces carbon footprint and enhances brand reputation. |

| Advanced Manufacturing | Utilization of automation and AI in designing and producing rigid flex circuits. | Consumer products, automotive electronics, and IoT devices. | Increases efficiency and reduces production costs. |

| Flexible Display Technologies | Integration of rigid flex circuits with flexible display technologies for better user experience. | Smartphones, tablets, and automotive dashboards. | Enhances design possibilities and user interactivity. |

| 5G Connectivity | Increased demand for high-frequency circuits in 5G applications driving rigid flex advancements. | Telecommunications equipment, smart cities, and autonomous vehicles. | Boosts data transmission speeds and connectivity. |

Related Posts

-

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

-

What is a Flex Circuit? Benefits, Applications, and Key Considerations Explained

-

Top 10 Benefits of Using Flexible Printed Circuit Boards in Modern Electronics

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

What is PCB Fabrication The Complete Guide to Understanding PCB Manufacturing

-

2025 Strategies for PCB Prototyping to Improve Product Development Efficiency