2026 Top Trends in Fast PCB Manufacturing Technologies and Innovations?

The fast PCB manufacturing landscape is evolving rapidly. As industries demand quicker turnaround times, companies are adopting innovative technologies. A recent report from PCB Magazine indicates that the global PCB market is expected to reach $100 billion by 2026. This growth is driving the need for faster production processes.

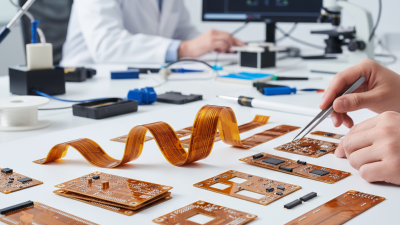

Emerging trends in fast PCB techniques include automation and advanced materials. Automation reduces human error and increases efficiency. Additionally, flexible printed circuit boards are gaining traction due to their adaptability. However, challenges remain. Not all manufacturers can keep up with demand. Quality control becomes a critical issue when speed is prioritized.

In this dynamic environment, companies must balance speed and quality. Continuous improvement is essential. Many businesses may struggle with integrating new technologies effectively. Future success in the fast PCB sector relies on overcoming these obstacles while innovating.

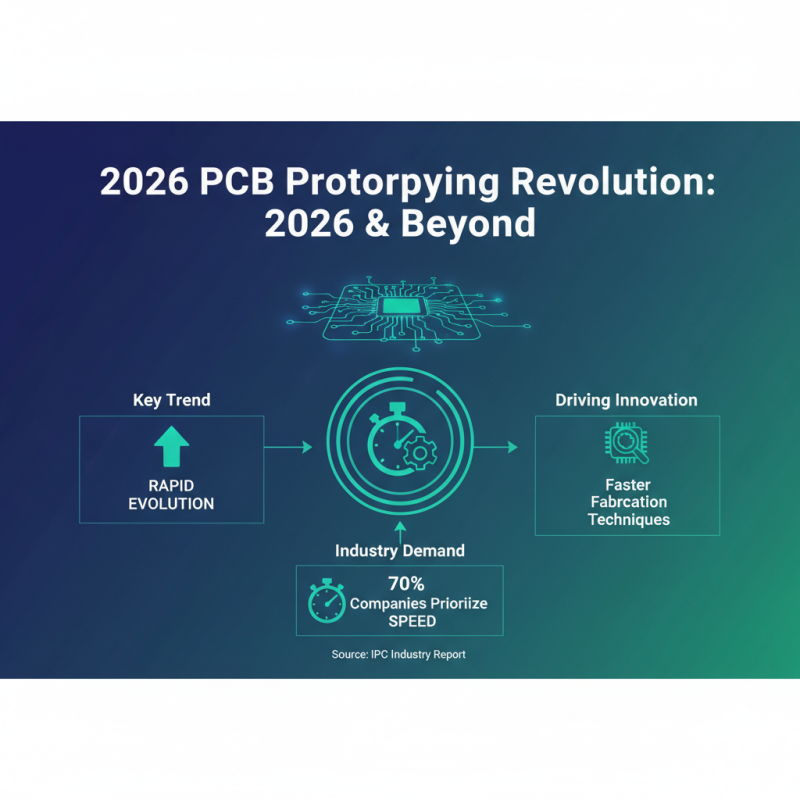

Emerging Trends in Fast PCB Prototyping Techniques for 2026

In 2026, fast PCB prototyping techniques are evolving rapidly. The need for quick turnaround times is critical for electronics development. According to the latest industry report by IPC, about 70% of companies emphasize speed in prototyping as a key priority. This demand drives innovations in fabrication methods.

One notable trend is the use of additive manufacturing. This technique allows for the creation of complex geometries. A recent study indicates that using 3D printing methods can reduce prototyping time by nearly 50%. However, challenges remain. Inconsistencies in material properties can lead to reliability issues.

Another emerging trend is the integration of AI in the design process. AI can enhance the accuracy of design verification. It can also predict potential failures before production, which is crucial. Yet, there is a need for skilled personnel to interpret AI data effectively. Many teams still lack this expertise.

Advancements in Automated PCB Assembly Technologies and Their Impact

The realm of automated PCB assembly technologies is evolving rapidly. These advancements promise to reshape the future of electronics manufacturing. High-speed pick-and-place machines are becoming the norm, allowing for faster assembly and increased precision. These machines often operate without human intervention, reducing the risk of errors. Yet, reliance on automation presents challenges. Human expertise is still crucial for troubleshooting issues that machines may overlook.

Moreover, innovations in AI and machine learning are enhancing defect detection. Cameras equipped with smart algorithms analyze each PCB for imperfections. This technology speeds up the quality control process significantly. However, it is not always foolproof. The technology can misinterpret certain issues, leading to potential oversights. Companies must balance technology use with human judgment.

The integration of robotics and automation streamlines processes, yet there are concerns about job displacement. Employees may feel uncertain about their roles in this changing landscape. Training programs are needed to help workers adapt to new technologies. The path forward demands a thoughtful approach that merges human skill with automated efficiency. Continuous reflection on these dynamics will be essential for the industry's success.

Innovations in PCB Materials Enhancing Performance and Speed

In recent years, innovations in PCB materials have transformed manufacturing processes. Advanced materials like high-frequency laminates and flexible substrates are improving performance significantly. For instance, a report by IPC states that the use of these materials can increase signal integrity by 30%. This is particularly vital in high-frequency applications.

Furthermore, new resin formulations are enhancing thermal performance. These resins can handle higher temperatures and reduce the risk of delamination. A study found that PCBs made with new composite materials show a 25% increase in thermal conductivity. However, sourcing these advanced materials can pose a challenge. Not all manufacturers can access the latest innovations.

As designs become more complex, the demand for these high-performance materials rises. Yet, many companies are still hesitant to invest fully in these innovations. They worry about costs and integration difficulties. This hesitation reflects a broader industry challenge: balancing innovation with practical implementation.

2026 Top Trends in Fast PCB Manufacturing Technologies and Innovations

The Role of AI and Machine Learning in PCB Manufacturing Efficiency

The role of AI and machine learning in PCB manufacturing has surged. These technologies automate tasks and analyze data quickly. This enhances production efficiency significantly. AI can predict failures, reducing downtime. That means fewer delays in the manufacturing process.

Consider implementing AI-driven tools. They improve quality control. Machines learn from past errors. This leads to fewer defects and higher precision. The integration of machine learning also streamlines workflows. It simplifies complex production tasks and increases speed.

However, be cautious. AI is not a magic solution. It needs constant monitoring. Data integrity is crucial. A small error in data can lead to big problems. Regular assessments of AI outputs are vital. This ensures reliability and continuous improvement in PCB manufacturing efficiency.

Sustainability Practices Impacting Fast PCB Production in 2026

In 2026, sustainability practices are reshaping fast PCB manufacturing. As environmental concerns rise, the industry focuses on reducing its carbon footprint. More companies are exploring eco-friendly materials. These materials often include biodegradable options and recycled components.

Innovations in energy-efficient production methods are gaining traction. Technologies like solar-powered manufacturing facilities are becoming popular. Factories are implementing waste reduction strategies, aiming to minimize leftover materials. These changes promote circular economy principles. However, the transition is not without challenges. Many manufacturers struggle to adopt new practices while maintaining efficiency.

Collaboration with suppliers is crucial for sustainable progress. By working together, companies can share resources and knowledge. They can overcome obstacles related to sourcing sustainable materials. This collective effort ultimately drives the industry toward a greener future. Still, the pace of change may not be fast enough to satisfy all stakeholders. The need for improvement remains a constant reflection point in the journey to sustainability.

2026 Top Trends in Fast PCB Manufacturing Technologies and Innovations

| Trend | Description | Impact on Sustainability | Projected Adoption Rate |

|---|---|---|---|

| Automated Production Lines | Implementation of AI and robotics for faster production. | Reduces waste and energy consumption through efficiency. | 75% |

| Eco-Friendly Materials | Usage of biodegradable and recyclable materials in PCB design. | Lowers environmental impact and supports recycling initiatives. | 65% |

| Advanced PCB Layout Software | Utilization of high-end software for optimized designs. | Minimizes material use and enhances performance. | 80% |

| 3D Printing | Adoption of 3D printing technology for custom circuit boards. | Reduces unnecessary material and allows for on-demand production. | 70% |

| Smart Manufacturing | Integration of IoT devices for real-time monitoring. | Enhances resource management and reduces waste. | 85% |

Related Posts

-

2025 Strategies for PCB Prototyping to Improve Product Development Efficiency

-

What is PCB Fabrication The Complete Guide to Understanding PCB Manufacturing

-

Understanding the Essential Role of Printed PCBs in Modern Electronics

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development

-

2025 How to Choose the Right Flex Printed Circuit Board for Your Needs