Top 10 Best Printed Circuits Designs for Electronics in 2023

In the ever-evolving realm of electronics, the significance of printed circuits cannot be overstated. As of 2023, the global printed circuit board (PCB) market is projected to reach an impressive valuation of approximately $80 billion, reflecting an annual growth rate of around 5% according to industry reports. This growth is propelled by the increasing demand for advanced electronic devices across various sectors, including telecommunications, automotive, and consumer electronics. The proliferation of smart technologies and IoT devices further amplifies the importance of efficient printed circuits, making their design and manufacturing pivotal for innovation.

The innovations in printed circuits are not merely a reflection of market demands but also an opportunity for manufacturers to enhance performance while minimizing costs. Cutting-edge techniques such as high-density interconnect (HDI) technologies and flexible circuit designs are leading the charge in revolutionizing electronics. Moreover, sustainability has become a crucial aspect, with an emphasis on eco-friendly materials and processes resonating within the industry. As we delve into the top design trends for printed circuits in 2023, it is essential to recognize how these developments address both performance demands and environmental considerations, shaping the future of electronic devices globally.

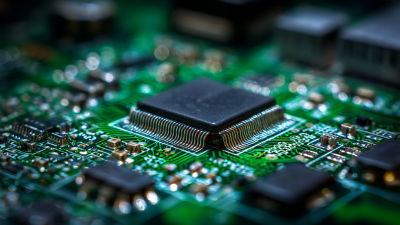

Overview of Printed Circuit Board (PCB) Technology in 2023

In 2023, the landscape of Printed Circuit Board (PCB) technology continues to evolve, driven by advances in materials, design methodologies, and manufacturing processes. One of the most significant trends this year is the shift towards flexible and high-density interconnect PCBs. These innovations allow for more compact and lightweight designs, which are essential for modern electronics used in smartphones, wearables, and IoT devices. The ability to incorporate multiple functionalities into a smaller footprint without sacrificing performance is revolutionizing the way designers approach electronic product development.

Additionally, there has been a marked emphasis on eco-friendly manufacturing practices within the PCB industry. Growing awareness of environmental sustainability is leading to the adoption of greener materials and processes, including lead-free solder and recyclable substrates. As regulations tighten and consumers demand more environmentally conscious products, PCB manufacturers are increasingly investing in technologies that reduce waste and energy consumption. This focus not only supports compliance with global standards but also aligns with the broader trend of sustainable electronics in the market. As new innovations emerge, 2023 is set to be a pivotal year for the future of PCB technology, highlighting the industry's commitment to both performance and sustainability.

Key Features to Consider in PCB Designs for Electronics

When designing printed circuit boards (PCBs) for electronics in 2023, several key features are essential to ensure optimal performance and reliability. First, the layout and routing of components play a crucial role in minimizing signal interference and maintaining signal integrity. A well-organized schematic can enhance the flow of electricity while reducing chances of errors during manufacturing. Additionally, thermal management is a significant factor; proper heat dissipation can prevent overheating and prolong the lifespan of electronic devices.

Tip: Always consider using a multilayer design when dealing with complex circuit requirements. This allows for more routing possibilities and can help in organizing power and ground layers effectively, which is vital for reducing electromagnetic interference.

Another important aspect is the choice of materials. The substrate material should be chosen based on the specific application, balancing factors like flexibility, durability, and cost. High-frequency applications may require specialized materials to support efficient signal transmission. Moreover, incorporating vias and pads appropriately can aid in enhancing mechanical strength and functionality.

Tip: Conduct regular design reviews and simulations during the development process. This practice can catch potential issues early, saving time and resources by ensuring that your PCB design meets all specifications before moving to production.

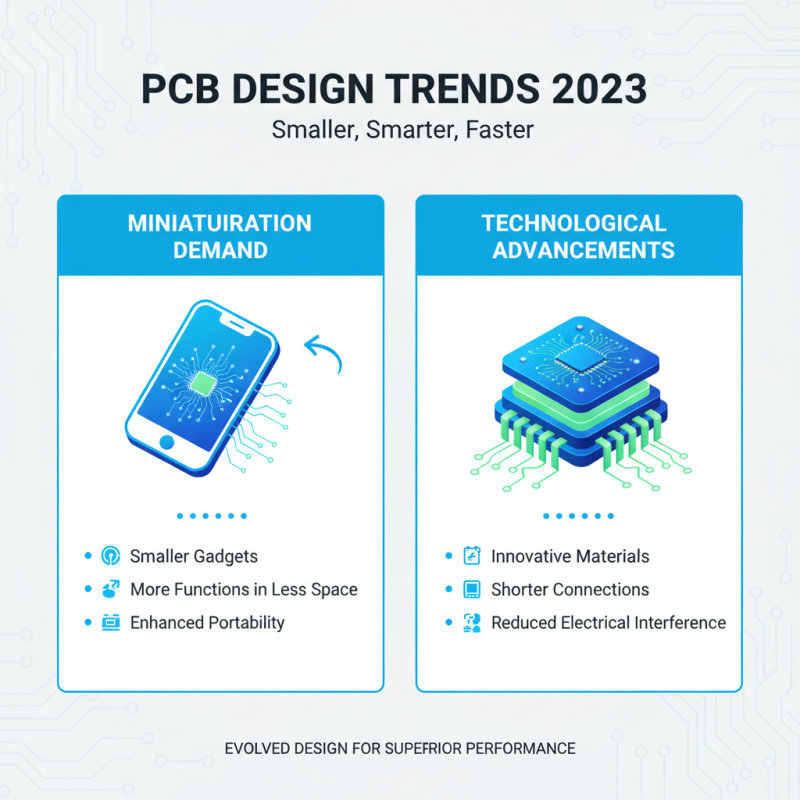

Top Trends Influencing PCB Design Choices in 2023

In 2023, printed circuit board (PCB) design has evolved significantly, driven by several key trends. One prominent influence is the growing demand for miniaturization in electronic devices. As technologies advance, consumers expect smaller and more efficient gadgets, prompting designers to rethink traditional layouts and explore innovative materials that can accommodate more functionality within a compact space. This trend not only enhances portability but also improves overall performance by reducing the length of connections and electrical interference.

Moreover, sustainability has become a cornerstone in PCB design choices this year. With increasing awareness of environmental issues, many designers are focusing on eco-friendly materials and manufacturing processes. This shift includes utilizing recyclable substrates, reducing waste during production, and ensuring that end-of-life products can be safely disposed of or repurposed. Adopting sustainable practices not only meets regulatory demands but also appeals to environmentally conscious consumers.

**Tip:** When designing PCBs, consider adopting multi-layer designs to save space. This approach can significantly enhance performance while allowing for a smaller footprint.

**Tip:** Always keep an eye on new materials and technologies that can help advance your PCB designs. Staying updated with industry innovations can give you a competitive edge and align your products with current market trends.

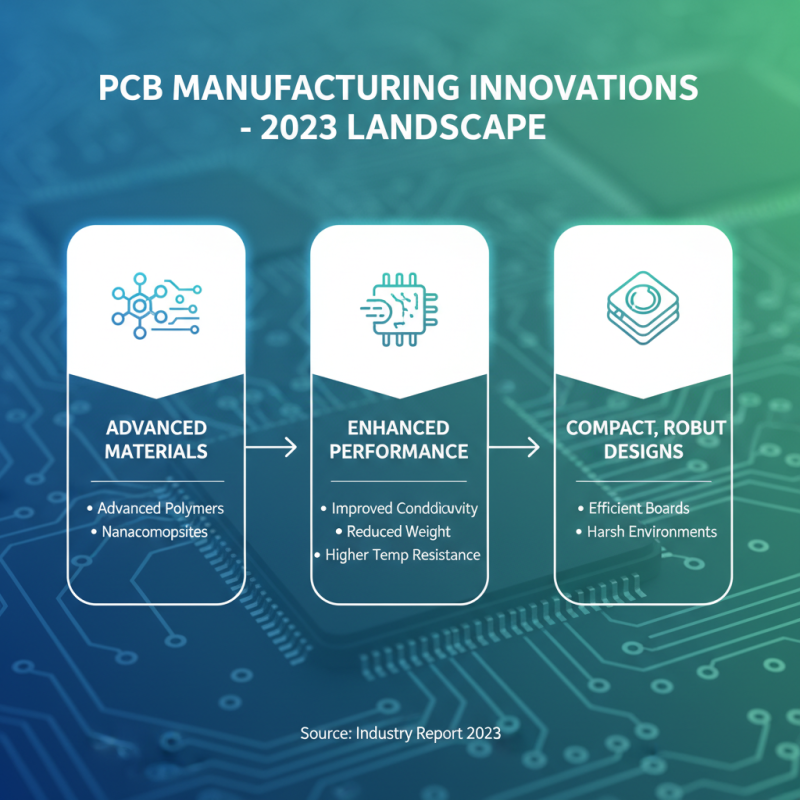

Innovative Materials Used in PCB Manufacturing This Year

The landscape of printed circuit board (PCB) manufacturing in 2023 has been significantly influenced by the advent of innovative materials. Manufacturers are increasingly turning to advanced polymers and nanocomposites to enhance the performance and durability of PCBs. These materials not only improve conductivity but also reduce weight, making them ideal for use in compact electronic devices. With the integration of these innovative substrates, designers are able to create more efficient boards that can withstand higher operating temperatures and harsh environments.

Another trend shaping PCB manufacturing this year is the use of biodegradable materials, which aligns with the growing emphasis on sustainability in the electronics industry. These eco-friendly options aim to minimize environmental impact without compromising performance. By adopting such materials, manufacturers can cater to a more environmentally conscious market while still delivering high-quality, reliable circuits. This movement towards sustainable practices signifies a shift in how the industry approaches material selection, promising a future where electronic components are both advanced and responsibly sourced.

Leading Companies in PCB Design and Production in 2023

In 2023, the landscape of printed circuit board (PCB) design and production is characterized by innovation and technological advancements, with several leading companies pushing the boundaries of what is possible in electronics. These companies are at the forefront of integrating cutting-edge techniques such as automated design tools, advanced materials, and sustainable manufacturing processes. Their expertise in meeting the demands of industries ranging from consumer electronics to automotive and medical devices underscores the importance of PCBs in contemporary technology.

Collaboration and research have become key themes as these companies invest heavily in R&D to enhance the efficiency and reliability of PCB designs. They are exploring new fabrication methods, including additive manufacturing and flexible circuits, to cater to specialized applications. Furthermore, the emphasis on miniaturization and connectivity in electronic devices has driven these firms to develop compact, high-performance PCBs that can support the latest advancements in IoT and smart technologies. By focusing on quality, reliability, and design versatility, leading PCB manufacturers are equipped to meet the evolving needs of the electronics industry in 2023 and beyond.

Related Posts

-

Mastering Circuit Board Design Fundamentals for Beginners in Electrical Engineering

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

Top 10 Benefits of Using Flexible Printed Circuit Boards in Modern Electronics

-

Why Printable Circuit Boards are Revolutionizing Modern Electronics Design

-

How Printed Circuit Boards Shape the Future of Technology with Insights from Industry Trends

-

What is PCB Fabrication The Complete Guide to Understanding PCB Manufacturing