How to Choose the Right Rigid Flex Circuit for Your Project?

Choosing the right rigid flex circuit for your project is a critical task. The perfect circuit can significantly impact functionality and performance. Rigid flex circuits combine the best of both worlds: rigid boards and flexible substrates. Their versatility makes them a popular choice in various applications, from medical devices to consumer electronics.

Understanding the specific needs of your project is essential. Do you require high durability? Consider the materials used. Is space a concern? Evaluate the design options in rigid flex circuits. Each choice you make will influence the overall success. Many engineers overlook important factors. They often focus solely on cost, neglecting quality and performance.

You might encounter obstacles in the selection process. Not every rigid flex circuit suits every application. It’s important to reflect on your project's unique requirements. Take time to assess not just the specifications but also the long-term implications. This reflection can lead to better decision-making and ultimately a more successful outcome.

Understanding Rigid Flex Circuits and Their Applications

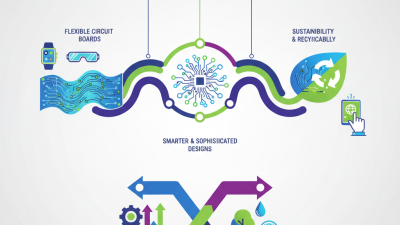

Rigid flex circuits are a unique blend of rigid and flexible technology. They combine the robustness of rigid boards with the adaptability of flexible ones. This makes them ideal for various applications. For instance, in aerospace, the lightweight design helps save fuel. In medical devices, these circuits enable compact layouts in small devices.

Choosing the right type is crucial. You need to think about your project's requirements. For instance, consider the operating environment. Will it face high temperatures? Is space limited? These factors affect performance. Additionally, understanding the complexity of the design is vital. A complex circuit may require advanced manufacturing techniques. This could lead to higher costs and longer lead times. Don't overlook these details.

Sometimes, it’s hard to strike the right balance. Cost versus performance can be tricky. Focusing too much on cost may compromise quality. Reflecting on priorities helps make better decisions. Each application presents unique challenges. Being aware of them can ultimately lead to a more successful project.

Key Factors to Consider When Selecting Rigid Flex Circuits

Selecting the right rigid flex circuit for your project involves various key factors. Understanding your project's needs is essential. Consider the environment where the circuit will operate. High temperatures? Humidity? These conditions can impact performance. Always think about how the circuit's flexibility might be utilized. Can it bend without compromising function?

Tips: Review material specifications. Not all materials are equal. Use flexible materials that meet your durability standards. Evaluate thickness and layer counts. This affects strength and flexibility.

Another crucial factor is design complexity. Complex designs may require more intricate manufacturing processes. This could lead to increased costs and longer lead times. Prioritize simplicity in design where possible. This could save time and resources.

Tips: Collaborate closely with engineers. Communication can clarify expectations. Discuss potential challenges early to avoid delays. Always keep manufacturability in mind. It ensures that your designs can be produced effectively without costly reworks.

Comparison of Rigid Flex Circuits with Traditional PCB Options

When it comes to electronic design, choosing between rigid flex circuits and traditional PCBs can be challenging. Rigid flex circuits offer unique advantages. They combine flexibility with durability. This allows for efficient use of space. On the other hand, traditional PCBs are often simpler and more cost-effective for basic applications.

One clear difference lies in design complexity. Rigid flex circuits can accommodate more complex layouts. They allow more freedom in component placement. However, the manufacturing process can be more intricate. This complexity may lead to unforeseen delays. Some designers may underestimate the additional lead time required.

Another aspect is reliability. Rigid flex circuits tend to perform better in dynamic environments. They resist vibration and movement. However, they can be less forgiving when it comes to design mistakes. If a mistake is made, correcting it may be more targeted. It's essential to evaluate the specific needs of the project before making a decision. Consider factors like space constraints, environmental exposure, and budget.

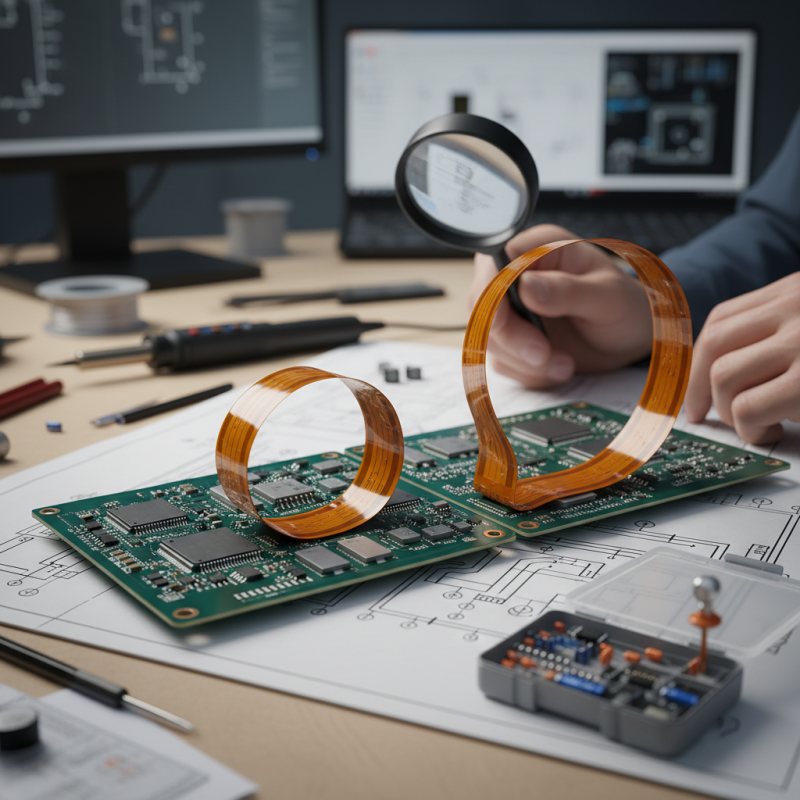

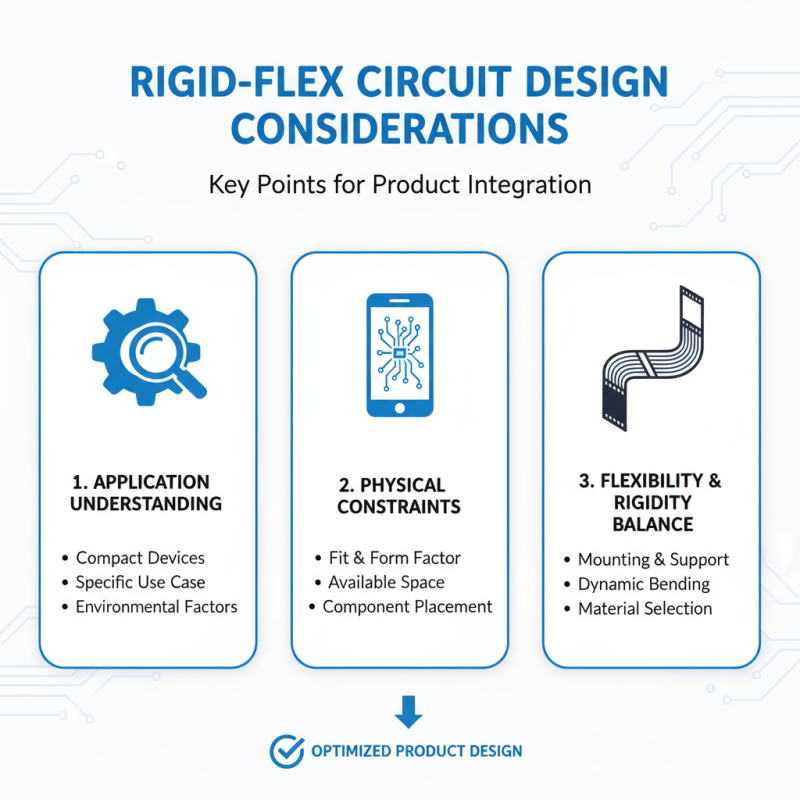

Design Considerations for Rigid Flex Circuit Integration

When integrating rigid flex circuits into your project, there are crucial design considerations to keep in mind. The first step is understanding the specific application. Rigid flex circuits are often used in compact devices. Ensuring the design fits within the physical constraints of your product is essential. Flexibility must be balanced with the rigid areas for mounting and support.

Material selection is another vital aspect. Different materials can affect performance and reliability. Consider factors such as thermal conductivity and mechanical strength. It’s important to reflect on your project's unique requirements. Small decisions, like trace width and layer stack-up, can lead to significant impacts. Don't overlook the importance of the manufacturing process. A misstep can compromise the whole design.

Moreover, testing and validation are critical. Prototypes often reveal unforeseen issues. These could range from signal integrity problems to mechanical failures. Iterating designs based on feedback is key. Embrace the idea that imperfections will arise. Each flaw offers a chance to refine your design. Adjustments based on real-world testing can lead to a more robust final product.

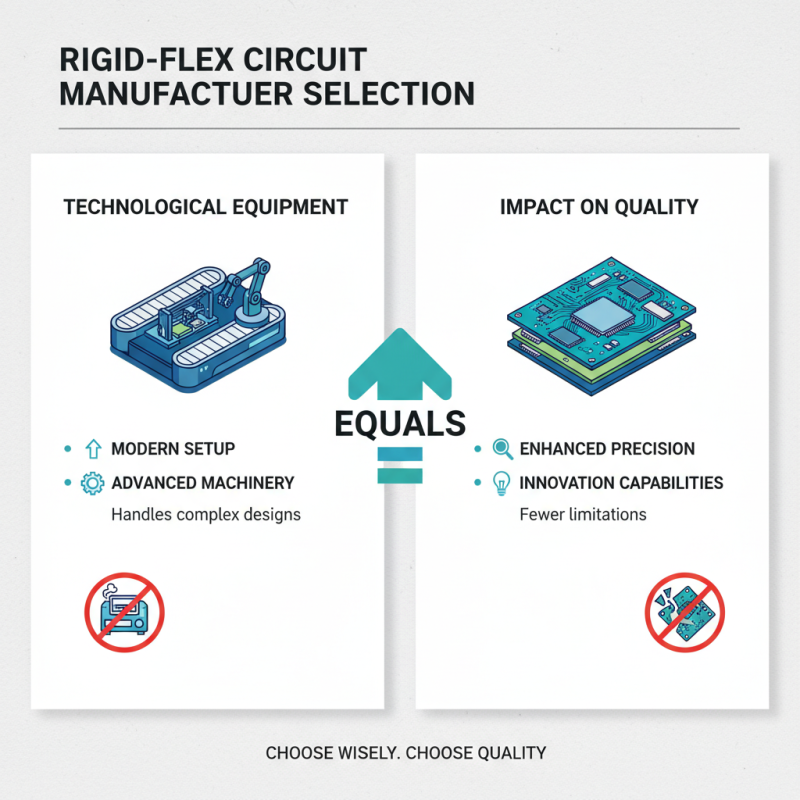

Evaluating Manufacturer Capabilities for Rigid Flex Circuit Production

When selecting a manufacturer for rigid flex circuit production, it's essential to evaluate their capabilities thoroughly. Start with their technological equipment. A modern setup can significantly impact the quality of the circuits produced. Check if they utilize advanced machinery that can handle complex designs, because older equipment may limit potential innovations.

Next, consider their experience in the industry. A manufacturer with years of expertise is more likely to understand the nuances of rigid flex circuits. They should also have a proven track record in delivering reliable products. Don't overlook the importance of staff training and skill sets. A well-trained workforce can mean the difference between a successful project and unexpected failures.

Communication is often overlooked but is vital. A manufacturer should be open and responsive. If they are not prompt in addressing queries, it might be a red flag. Remember that the choice of a manufacturer can directly affect your project’s timeline. Poor capability can cause delays, leading to frustration. Make sure to ask for references. Previous clients can provide insights into their experience. Understanding both strengths and weaknesses can help in making an informed decision.

Related Posts

-

Top 10 Benefits of Rigid Flex PCB for Electronics Design?

-

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

-

What is a Flex Circuit? Benefits, Applications, and Key Considerations Explained

-

2026 Top Rigid Flex Technology Trends You Need to Know?

-

Top Circuit Boards Technologies Transforming Electronics Today?

-

Why Understanding PCB Production is Essential for Modern Electronics