Top Factors Influencing PCB Production Quality and Cost?

In the world of PCB production, quality and cost are influenced by numerous factors. According to Dr. John Smith, a renowned expert in PCB technologies, "Achieving high-quality standards often comes at a price, but neglecting them can lead to greater costs down the line." His words resonate deeply in an industry where precision is crucial.

Various elements impact PCB production, such as material selection, design complexity, and manufacturing processes. Choosing the right materials is vital for durability and performance. Complex designs can increase production time and cost. Companies must balance these factors carefully to maintain profitability.

While striving for excellence, some challenges may arise. Not all factories adhere to the same standards. Disparities in processes can lead to inconsistencies. It’s essential for businesses to reflect on their operations and continually seek improvements. By focusing on key factors, the PCB production industry can evolve and meet the ever-growing demands of technology.

Key Material Selection and Its Impact on PCB Quality and Cost

When it comes to PCB production, material selection significantly affects both quality and cost. High-quality materials lead to better performance and lower defect rates. Lower-grade materials might cut costs initially but often result in more expensive failures later. Choosing the right laminate, copper thickness, and solder mask can make a big difference.

Tips: Always ask for samples before large orders. This helps ensure the materials meet your quality expectations. Test them under your specific conditions to avoid unforeseen issues.

The trade-offs between costs and quality are essential. Sometimes, a cheap PCB may save money upfront but can lead to higher repair costs. Ensure you evaluate the long-term consequences of material quality. Discuss these factors with your production team. Collaborate to find the best balance that suits your needs.

Consider the PCB design intricately. A complex design might require higher-grade materials for reliability. If you're cutting corners on material, be ready for potential issues down the line. Reflect on your choices regularly to adapt as market demands evolve.

Top Factors Influencing PCB Production Quality and Cost

Manufacturing Processes and Their Role in PCB Production Efficiency

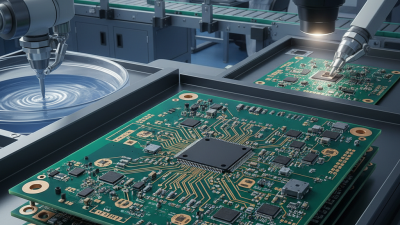

The manufacturing process greatly influences PCB production efficiency and quality. Each step, from design to assembly, plays a critical role. For instance, the etching process requires precision. Even a slight error can lead to significant defects in the final product. Similarly, improper handling during the soldering phase can compromise connections. It’s essential to monitor every detail closely.

Quality inspection is often overlooked. Many manufacturers rush this phase to save time. However, this can be detrimental. Inconsistent quality control may lead to higher costs in the long run. Components can fail, leading to recalls and waste. Investing time in thorough inspections can drastically reduce errors.

In terms of material selection, choices should not be based solely on cost. Cheaper materials might be tempting but can affect performance. The balance between cost and quality is delicate. Sometimes, using higher-quality materials results in longer-lasting products. Reflection on these factors is necessary for optimizing efficiency in PCB production.

Quality Control Measures for Ensuring High-Grade PCB Outputs

Quality control plays a critical role in PCB production. In this highly competitive industry, achieving high-quality outputs is essential. According to a recent industry report, over 40% of PCB defects stem from inadequate quality control processes. This emphasizes the necessary vigilance in inspection and testing throughout production.

Implementing effective quality assurance measures can significantly reduce costs associated with defects. For instance, meticulous incoming material inspections can identify issues early. Utilizing automated optical inspection technology helps prevent defects during assembly. Additionally, regular training sessions for staff on quality standards ensure everyone is aligned with the best practices.

While these measures improve quality, they require continuous evaluation. Not all processes deliver consistent results. For example, a study found that around 30% of inspections miss critical defects. Companies must evaluate their quality control systems regularly. They should adapt to evolving technologies and market demands. This reflection helps maintain a balance of cost-effective production while ensuring high-grade outputs.

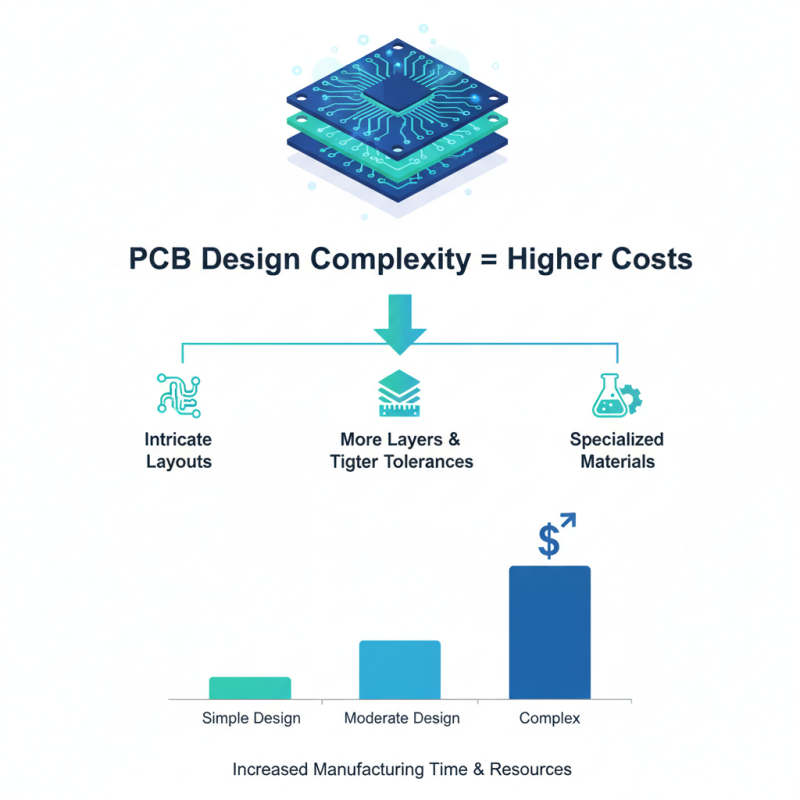

Cost Implications of PCB Design Complexity and Specifications

The complexity of PCB design significantly impacts production costs. When designers opt for intricate layouts, it often leads to increased manufacturing time and resources. Complex specifications can entail more layers, tighter tolerances, and specialized materials, which drive up costs. Every added layer may seem minor, but it accumulates in expenses.

Additionally, the choice of specific components can alter a PCB's cost. High-frequency and high-speed components frequently require advanced design considerations. These specifications can complicate the assembly process, leading to potential mistakes. Errors arising from intricate designs may not be apparent until late in production. This is a costly oversight, resulting in rework and wasted materials.

Designers must strike a balance between functionality and cost-efficiency. While advanced features may enhance performance, they also inflate the budget. Projects can suffer from scope creep, with specifications becoming more elaborate over time. A simpler design may suffice and save significant expenses. Reflection on the necessity of each feature is vital in maintaining an optimal cost-to-performance ratio.

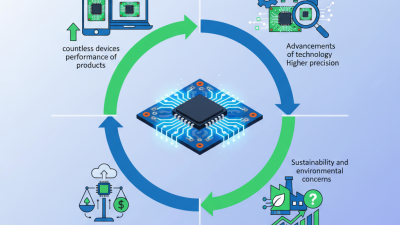

Technological Advances Shaping PCB Production Costs and Quality Standards

The landscape of PCB production is rapidly shifting due to technological advances. Improved manufacturing techniques are crucial for achieving higher quality standards and reducing costs. Automation and smart manufacturing are rising trends that enhance precision. These innovations contribute to consistent results. However, they require significant investment and training.

Monitoring production processes is also essential. Implementing quality control measures can help catch errors early. This reduces waste and saves money. Adopting real-time data analytics can optimize production flow, ensuring resources are used efficiently.

Tip: Regularly assess your production workflow. Identify areas where technology can minimize manual errors.

However, not all changes bring immediate benefits. Adjusting to new technologies can disrupt existing workflows. Staff may need time to adapt. Small manufacturers might struggle with the initial costs. Investing in new technology is a balancing act.

Tip: Consider phased implementation. This could ease the transition while maintaining current output. Making gradual adjustments could optimize your production quality over time.

Top Factors Influencing PCB Production Quality and Cost

| Factor | Impact on Quality | Impact on Cost | Technological Influence |

|---|---|---|---|

| Material Selection | High quality materials improve performance | Higher costs for premium materials | Advancements in material science |

| Fabrication Process | Precision processes enhance reliability | Complex processes increase costs | Automation and robotics |

| Testing and Inspection | Thorough testing ensures functionality | Costs associated with advanced testing tools | AI in defect detection |

| Design Complexity | Complex designs can meet higher standards | Higher design costs | Advanced CAD software |

| Supply Chain Management | Efficient supply chains ensure timely delivery | Costs affected by logistics and sourcing | Blockchain for transparency |

Related Posts

-

What is PCB Production and How Does it Impact Electronics Industry?

-

What is PCB Fabrication and How Does it Impact Your Electronics Projects

-

Why Understanding PCB Production is Essential for Modern Electronics

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development

-

2025 Strategies for PCB Prototyping to Improve Product Development Efficiency

-

What is PCB Fabrication The Complete Guide to Understanding PCB Manufacturing