2026 How to Choose Fast PCB for Your Electronic Projects?

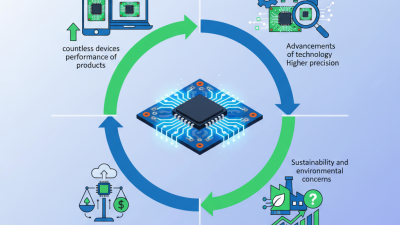

In today's fast-paced electronics industry, the demand for fast PCB (Printed Circuit Board) solutions is greater than ever. According to a recent report by IPC (Association Connecting Electronics Industries), the global PCB market is expected to grow by 4.5% annually, reaching a valuation of $80 billion by 2026. Fast PCBs are essential for projects requiring rapid prototyping and shorter time-to-market.

Industry expert Dr. Emily Carter, a leading figure in PCB innovation, emphasizes, "Speed in PCB manufacturing directly influences project success." This quote highlights the need for efficiency in the design and production processes. However, choosing the right fast PCB service can be challenging. Factors such as material quality, production speed, and cost-effectiveness must be carefully evaluated.

Yet, many engineers overlook these aspects, leading to suboptimal results. For instance, a circuit that doesn’t perform as expected may stem from poorly chosen fast PCB services. Balancing speed and quality is crucial. As projects grow more complex, the need for reliable and swift PCB solutions will only increase. Reflection on these variables can lead to more successful electronic projects.

Understanding the Basics of PCB for Electronic Projects

When starting an electronic project, understanding the basics of

printed circuit boards (PCBs) is crucial. A PCB acts as the backbone of any electronic device.

It provides a physical platform for components. The layout design determines how efficient your circuit will be.

Selecting the right PCB involves several considerations. Begin by thinking about the

size and shape. These factors are critical for your project. Ensure the board fits well

within your case or enclosure. Then, choose the layer count. A simple circuit might need just one layer,

while complex projects could require multiple layers for

signal integrity.

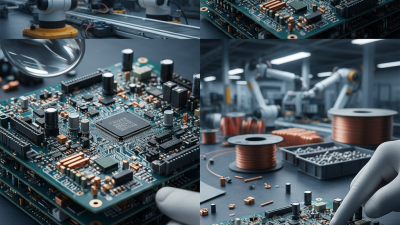

Material choice is another vital aspect. Common materials include FR-4 and

polyimide. Each has unique properties affecting heat resistance and flexibility.

Reflect on your specific project needs. Sometimes, the cheaper option may not provide the durability required.

Design challenges may arise unexpectedly, like trace width and

spacing issues. Addressing these can improve performance.

Embrace the learning process and adapt as necessary.

Key Factors to Consider When Choosing Fast PCB Services

When choosing fast PCB services, consider material quality. The right substrate impacts durability and performance. For instance, FR-4 is commonly used. However, high-frequency projects may benefit from advanced materials like Rogers. These can improve signal integrity, crucial for high-speed applications.

Turnaround time is another key factor. Studies show that 70% of projects face delays due to production issues. Fast PCB services should offer reliable timelines. Some providers promise delivery in as little as 24 hours. But be cautious; rush jobs can lead to compromised quality. Verify their track record.

Lastly, evaluate design support. Many firms provide design assistance or DFM checks to catch potential issues. According to industry reports, about 30% of PCBs require redesign. This often results in wasted time and resources. Good support can reduce errors and streamline production. Always prioritize a service that emphasizes quality alongside speed.

Evaluating PCB Manufacturers: Reliability and Speed

When choosing a fast PCB manufacturer for your electronic projects, evaluating reliability and speed is crucial. Research from IPC shows that 70% of quality issues arise from the manufacturing process. Selecting a manufacturer that emphasizes stringent quality control can help mitigate these risks. Look for a company that adheres to industry standards like IPC-A-600. These standards ensure boards meet high reliability and performance criteria.

Speed plays a key role in your project’s success. A recent survey indicated that 65% of engineers view lead time as a top priority. Many manufacturers offer expedited services, but these can vary in actual performance. Ask for their average turnaround times. A manufacturer claiming two-week delivery may not meet this consistently. Conducting due diligence by reviewing customer testimonials can provide insights into their reliability. Consider contacting past clients about their experiences.

Balance is essential when assessing these options. Fast delivery should not compromise quality. A low-cost, quick-turn manufacturer might cut corners. This could lead to significant issues later. In the end, a reliable manufacturer paired with adequate speed will enhance your project's outcome. Prioritize those that offer transparent communication and clear timelines.

2026 How to Choose Fast PCB for Your Electronic Projects? - Evaluating PCB Manufacturers: Reliability and Speed

| Manufacturer | Production Speed (Days) | Quality Rating (out of 5) | Max Layers | Prototype Cost ($) | Volume Production Cost ($ per unit) |

|---|---|---|---|---|---|

| Manufacturer A | 5 | 4.8 | 12 | 50 | 5 |

| Manufacturer B | 3 | 4.5 | 8 | 80 | 6 |

| Manufacturer C | 7 | 4.1 | 6 | 60 | 7 |

| Manufacturer D | 4 | 4.6 | 10 | 70 | 5.5 |

| Manufacturer E | 6 | 4.9 | 14 | 55 | 5.8 |

Cost Considerations in Fast PCB Procurement

When procurement decisions for fast PCB come into play, cost is a primary concern. According to industry reports, printed circuit board (PCB) manufacturing costs can vary by up to 30% depending on the design complexity and materials used. Complex layouts and high-frequency applications usually drive costs up. This shows the importance of balancing speed with budget.

Tips: Simplify your designs. A less complicated board can save you significant money. It’s also crucial to assess whether you need fast turns. If your timeline is flexible, consider standard production timelines to cut costs.

Another element to consider is the volume of PCBs needed. Recent data suggests that ordering in bulk can reduce individual piece costs by as much as 15%. However, over-ordering can lead to waste and excess inventory. Carefully estimate your requirements before placing an order to avoid the downsides of unused product.

Tips: Always keep a close eye on market prices. Prices can fluctuate based on the demand and specific materials. Being aware of these changes can help you negotiate better deals.

Tips for Streamlining Your PCB Design Process for Speed

When designing PCBs for speed, various factors need consideration. The design process directly impacts time to market. Studies show that streamlined design can cut project timelines by up to 30%. Improving communication among team members is vital. Clarity can reduce revisions and misunderstandings.

Tip: Use standardized components. This minimizes redesign efforts. Using commonly available parts can simplify sourcing and speed up production.

Another aspect is prototype testing. Testing early in the design phase can prevent costly last-minute changes. Around 40% of designs face delays due to unforeseen issues. Identifying problems sooner can lead to better outcomes.

Tip: Implement iterative design. Start with a basic prototype and refine it gradually. This approach allows for faster feedback and less rework. It's a practical method to keep the project adaptable.

Adopting these strategies will help in navigating the complexities of PCB design. Speedy designs can meet urgent market demands, but pitfalls remain. Reflecting on past projects helps avoid repeating the same mistakes. Keep pushing for improvements in the design process.

Related Posts

-

2025 Strategies for PCB Prototyping to Improve Product Development Efficiency

-

What is PCB Production and How Does it Impact Electronics Industry?

-

Top Factors Influencing PCB Production Quality and Cost?

-

Top 10 Benefits of Using Flexible Printed Circuit Boards in Modern Electronics

-

What is a Flex Circuit? Benefits, Applications, and Key Considerations Explained

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development