Why is Circuit Board Manufacturing Important in Technology?

In today's fast-paced technological landscape, circuit board manufacturing plays a vital role. These small yet powerful components form the backbone of most electronic devices. From smartphones to medical equipment, circuit boards are essential for functionality and performance.

However, the importance of circuit board manufacturing often goes unnoticed. Many consumers take these integral parts for granted. They do not realize the processes involved in creating these intricate boards. Precision and quality control are essential in this manufacturing sector. Even a tiny error can lead to failure in devices, causing significant setbacks.

Reflecting on this, we must understand that circuit board manufacturing is not just a task. It is an art that combines engineering and creativity. As technology advances, the demand for better and more efficient circuit boards grows. This underscores the need for continuous improvement and innovation in circuit board manufacturing.

The Role of Circuit Boards in Modern Electronics

Circuit boards serve as the backbone of modern electronics. They connect various components, allowing devices to function seamlessly. In smartphones, laptops, and home appliances, circuit boards are essential for effective communication between parts. Without them, devices would not perform well; they would be incomplete.

The manufacturing process of circuit boards is complex. Each board must be meticulously designed and tested. This requires precision to ensure reliability. However, imperfections can occur during production. Some boards may have flaws that affect performance. These issues often lead to a need for redesign or replacement, which can be costly and time-consuming.

In today's fast-paced tech environment, efficiency is critical. Manufacturers must keep up with rapid innovation. Sometimes, there’s pressure to cut corners. This can lead to compromises in quality. Even small mistakes in design can result in significant problems later. Reflecting on these challenges is vital for continuous improvement. It drives better practices and more reliable products in the long run.

The Process of Circuit Board Manufacturing Explained

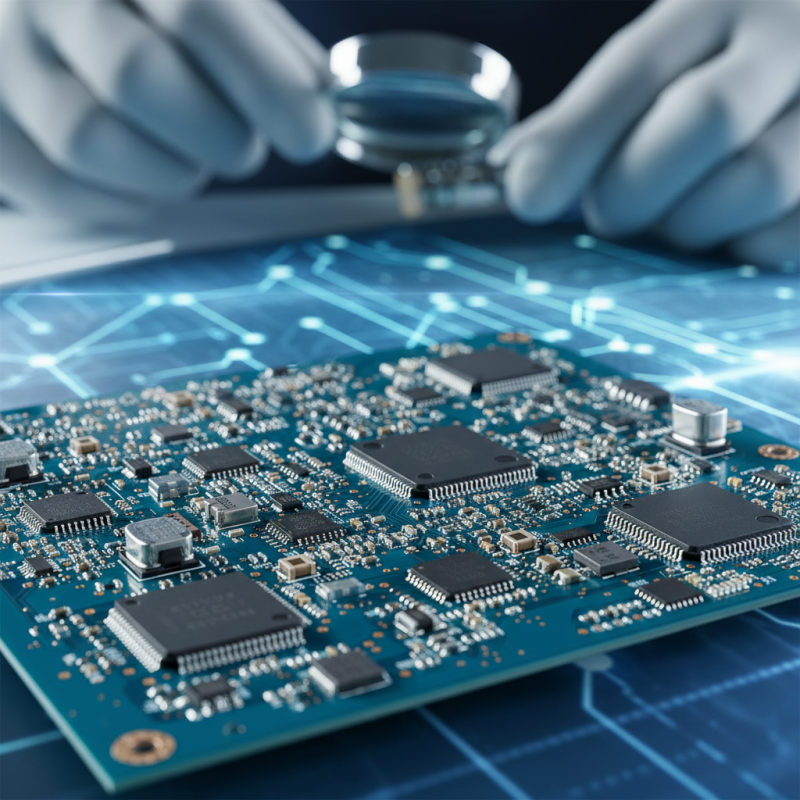

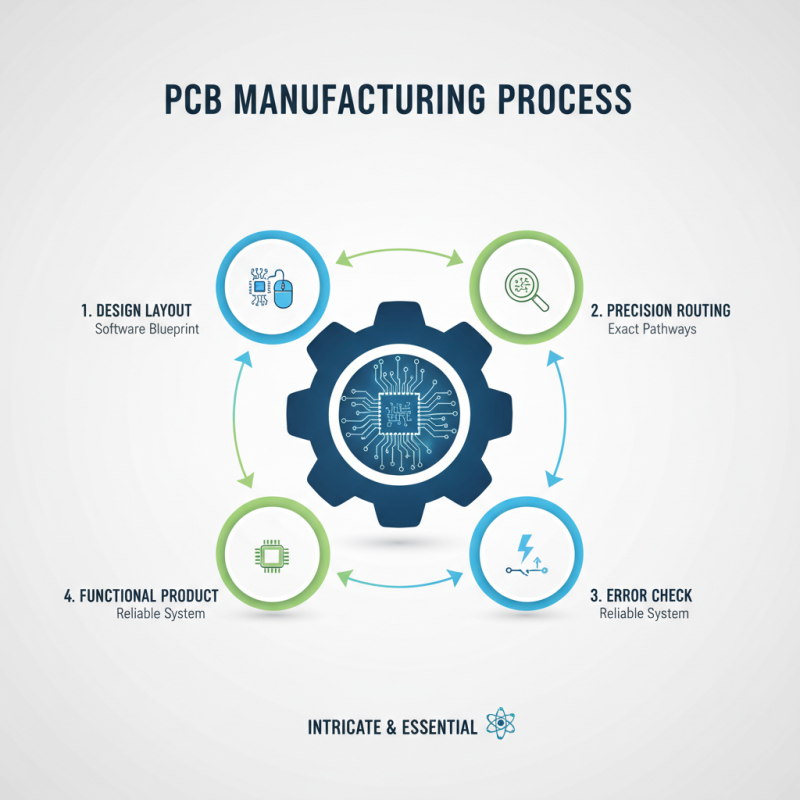

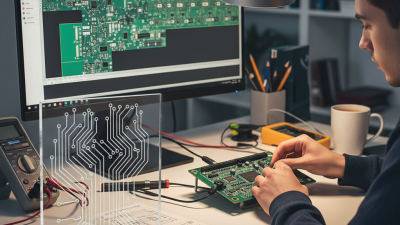

The process of circuit board manufacturing is both intricate and essential. At its core, it starts with designing a layout. Engineers use software to create a blueprint. This blueprint includes pathways for electrical connections. Each route must be precise. Minor errors can lead to system failures.

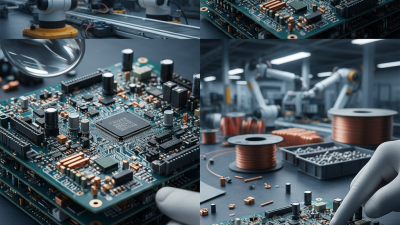

Once the design is confirmed, materials are selected. Typically, a copper-clad laminate is used. This ensures conductivity. The material is then etched. Chemical processes remove unwanted copper. What remains are the circuits. This step requires careful monitoring. Any oversight could result in flawed boards.

After etching, components are soldered onto the boards. This process is often automated. Yet, human oversight is still vital. Often, operators spot defects that machines may miss. Quality assurance plays a crucial role here. It ensures longevity and functionality. The entire process demands attention to detail and constant reflection on best practices. Technology relies on these boards, making their manufacturing significant.

Key Materials Used in Circuit Board Production

Circuit board manufacturing relies on a variety of essential materials. These materials ensure functionality and durability in electronic devices. The most common substrate is fiberglass, known for its excellent insulating properties. This lightweight material provides a sturdy base for the intricate circuits.

Another key component is copper. Copper traces on the board facilitate electrical pathways. Without these traces, signals cannot travel, rendering the circuit useless. However, producing quality copper layers can be challenging. Thickness and uniformity can vary, leading to inefficient performance in some products.

Moreover, solder masks and silkscreens are crucial. Solder masks protect the copper from oxidation, ensuring longevity. Silkscreen layers provide clarity in assembly, showing component placements. Yet, mastering these materials requires continuous learning. Mishaps can occur during production, affecting overall performance. Balancing quality and cost remains a constant struggle for manufacturers.

Challenges and Innovations in Circuit Board Manufacturing

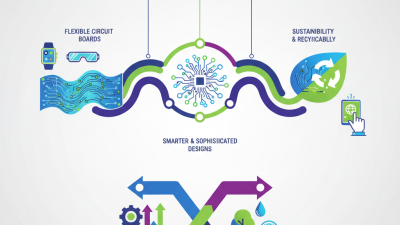

Circuit board manufacturing plays a vital role in technology. The process is not without its hurdles. Quality control remains a significant challenge. Small defects can lead to major failures. Ensuring that each circuit board meets industry standards is complex. Manufacturers often struggle with maintaining consistency.

Innovations in this field are necessary. Automation can help streamline processes. However, it can also introduce new issues. Machines can malfunction or misinterpret specifications. This creates a need for constant monitoring. Embracing advanced materials is another area of interest. Yet, finding a balance between cost and performance is tricky.

Sustainability is becoming a priority. Manufacturers are exploring eco-friendly materials. But the research is ongoing. Some methods are still unproven. The industry must reflect on these challenges. Despite the progress, there is still much to learn. Each step forward comes with its own set of questions.

Importance of Circuit Board Manufacturing in Technology

This bar chart illustrates the various challenges faced in circuit board manufacturing, emphasizing aspects such as production speed, cost efficiency, design complexity, quality assurance, and innovation level. Each dimension reflects critical factors impacting the manufacturing process in the technology sector.

Impact of Circuit Board Technology on Future Developments

The advancements in circuit board technology are reshaping various industries. According to a report by the Electronics Industry Association, the global demand for circuit boards is expected to grow at a CAGR of 5.3% from 2023 to 2030. This growth illustrates how integral circuit boards are to emerging technologies. For instance, smart devices and IoT applications rely heavily on PCB innovations to function effectively.

As circuit boards evolve, they enable the miniaturization and increased functionality of electronic devices. A study by ResearchAndMarkets suggests that flexible PCBs will dominate the market, driven by advancements in electronic packaging. However, manufacturers face challenges like material shortages and supply chain disruptions. These issues can impact the production timelines and costs of critical technologies.

Awareness regarding environmental sustainability is also rising. The industry must adapt to eco-friendly materials and recycling methods. Reports indicate that more than 25% of electronic waste stems from circuit board disposal. This statistic prompts manufacturers to reconsider their production practices. Balancing innovation with sustainability will be pivotal for future developments in circuit board technology.

Why is Circuit Board Manufacturing Important in Technology? - Impact of Circuit Board Technology on Future Developments

| Dimension | Description | Impact |

|---|---|---|

| Cost Efficiency | Reduction in manufacturing costs due to advanced technology. | Enables wider access to technology in various sectors. |

| Innovation | Facilitates the creation of smaller, faster, and more efficient circuits. | Drives technological advancements and new product development. |

| Sustainability | Adoption of eco-friendly materials and processes. | Reduces environmental impact and promotes corporate responsibility. |

| Customization | Ability to create tailored solutions for specific applications. | Enhances product performance and user satisfaction. |

| Integration | Integration of additional components like sensors and IoT modules. | Supports the growth of smart devices and interconnected systems. |

Related Posts

-

Mastering Circuit Board Design Fundamentals for Beginners in Electrical Engineering

-

Top Factors Influencing PCB Production Quality and Cost?

-

Top 10 Best Printed Circuits Designs for Electronics in 2023

-

How to Design Printed Circuit Boards for Beginners and Experts

-

Top 10 Circuit Board Design Techniques for Beginners to Master?

-

Top Circuit Boards Technologies Transforming Electronics Today?