Why Printable Circuit Boards are Revolutionizing Modern Electronics Design

The rise of printable circuit boards (PCBs) marks a transformative phase in modern electronics design, enabling unprecedented levels of customization and efficiency. According to a recent market research report by Smithers Pira, the global market for printable electronics is expected to reach over $40 billion by 2025, driven by advancements in materials and printing technologies. As manufacturers seek streamlined production processes and reduced costs, printable circuit boards offer a compelling solution that aligns with the growing demand for adaptable and sustainable electronic solutions.

Industry expert Dr. Emily Nguyen, a leading authority on printed electronics, emphasizes the significance of this innovation: "Printable circuit boards not only simplify the fabrication process but also open new avenues for integrating electronics into everyday objects, making them integral to the future of wearable technology and IoT devices." This shift highlights the ability of printable circuit boards to facilitate rapid prototyping and mass customization, addressing the unique needs of various sectors from consumer electronics to biomedical applications.

As we delve into the top five ways printable circuit boards are revolutionizing electronics design, it's essential to recognize their role in enhancing design flexibility, reducing manufacturing time, and fostering eco-friendly practices. The integration of this technology promises to reshape the landscape of electronic device manufacturing, making advancements previously thought to be unattainable a reality.

The Emergence of Printable Circuit Boards in Electronics Design

The emergence of printable circuit boards (PCBs) is transforming the landscape of electronics design, particularly through their miniaturization, which enhances both efficiency and reliability across various industries. These innovative boards, often no thicker than a piece of printer paper, are becoming the backbone of modern electronics, allowing for compact and lightweight designs that do not compromise on performance. This shift is notably evident in the automotive sector, where the printed circuit board market is poised for significant growth, indicating a robust demand for advanced electronic solutions in vehicles.

Tips: When designing PCBs, consider utilizing CAD software in conjunction with AI tools to streamline the process. This combination not only improves precision but also accelerates innovation in electronic design. Additionally, as companies seek cost-effective bulk solutions for PCB production, ensuring component authenticity becomes crucial. Look for manufacturers that provide transparent pricing and reliable quality assurance to safeguard your projects.

The advances in technology, such as the integration of AI in PCB design, are paving the way for smarter and more efficient electronic applications. As we witness this evolution, industry players must adapt to the rapid changes to stay competitive and leverage the benefits that printable circuit boards bring to the market.

Key Advantages of Printable Circuit Boards Over Traditional Methods

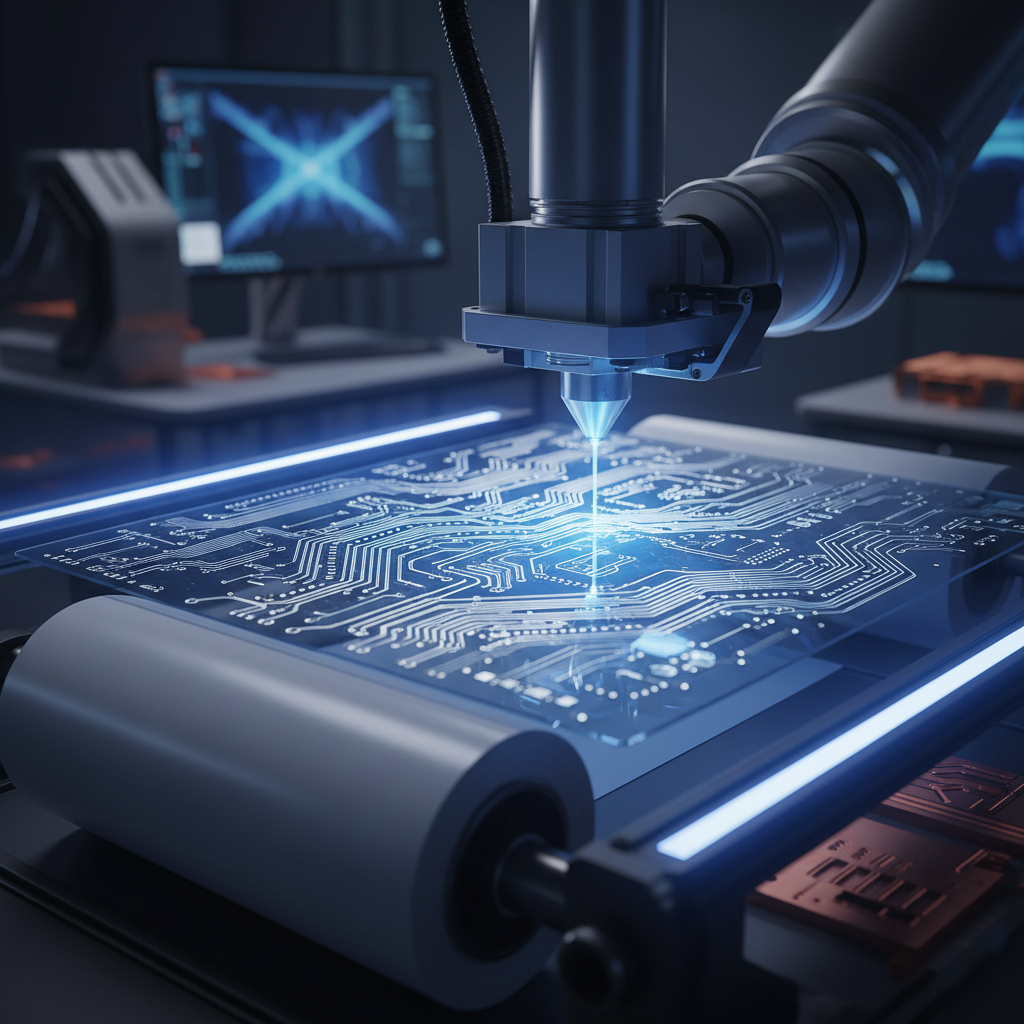

The advent of printable circuit boards (PCBs) is significantly transforming modern electronics design, offering several key advantages over traditional manufacturing methods. One of the most notable benefits is the ability to streamline the design process through more flexible configurations. Printable PCBs allow designers to create intricate patterns directly onto various substrates, which enhances design flexibility and facilitates rapid prototyping—essential for today's fast-paced market where speed to market is crucial.

Moreover, the integration of AI and CAD technologies further amplifies the advantages of printable PCBs. AI algorithms can optimize design layouts, predict manufacturing defects, and even adjust parameters in real time, ensuring a higher level of precision and efficiency. This synergy between AI and printable technology not only reduces lead times but also lowers production costs by minimizing material waste. As these innovations continue to evolve, they promise to redefine the future of electronics, paving the way for more efficient, sustainable, and cost-effective solutions in the industry.

Market Growth: Projected Value of Printable Electronics by 2025

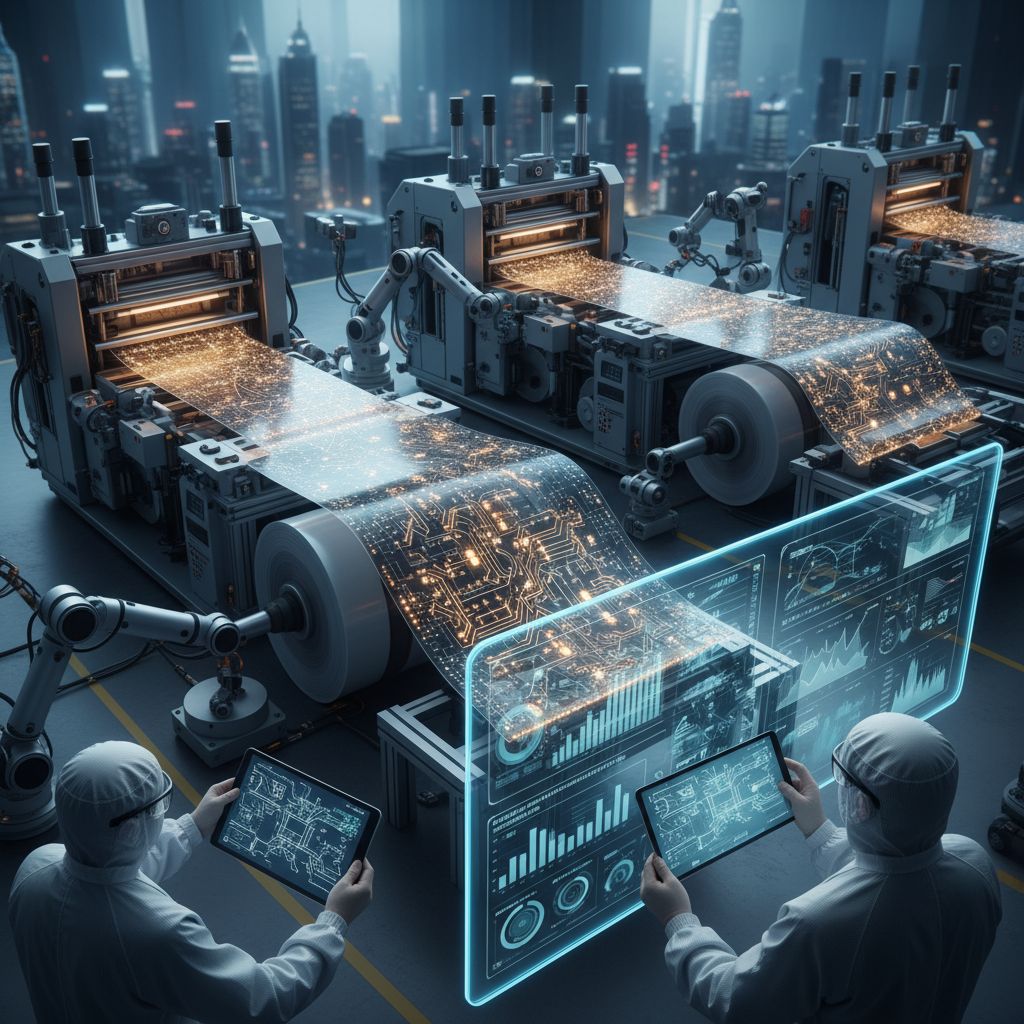

The market for printable electronics is projected to reach a remarkable value by 2025, driven by advancements in technology and the growing demand for innovative electronics solutions. As industries increasingly embrace sustainability and cost-effectiveness, printable circuit boards (PCBs) have emerged as a viable alternative to traditional manufacturing methods. With an estimated valuation of billions of dollars, this sector is poised for significant growth, reflecting the ongoing integration of electronics into everyday products.

Tips: When considering the use of printable circuit boards, companies should focus on their specific application needs. This technology particularly shines in prototyping and low-volume production, allowing for rapid iteration and testing. Furthermore, businesses should keep an eye on the materials being used, as advances in inks and substrates can greatly affect performance and reliability.

The scalability of printable electronics also contributes to its anticipated market expansion. As the technology matures, it offers flexibility that traditional rigid PCBs cannot match, adapting easily to various shapes and surfaces. By investing in printable circuit technology today, organizations can position themselves at the forefront of an electronics revolution, catering to the rising consumer expectations for multifunctional and sustainable devices.

Innovative Applications of Printable Circuit Boards in Consumer Electronics

Printable circuit boards (PCBs) are emerging as game-changers in consumer electronics, offering innovative applications that enhance both functionality and efficiency. The ability to print circuitry on flexible substrates allows designers to create lightweight, compact devices that were previously considered impractical. This technology not only reduces production costs but also accelerates the prototyping process, enabling rapid iterations and custom designs tailored to specific consumer needs. With advancements in materials, such as copper nanopowders estimated to reach a market value of $16.24 billion by 2025, the potential for incorporating high-performance components into printable circuits is significant.

The ongoing evolution in PCB design software is also noteworthy, as it plays a crucial role in optimizing designs for mass production. The global market for PCB design software continues to expand, driven by the demand for sophisticated electronic devices. This trend is complemented by the increasing emphasis on miniaturization in electronics, where printable PCBs provide the versatility needed for complex integration. With a projected market size increase from $74.12 billion in 2025 to $113.49 billion by 2032, the printable PCB technology stands poised to revolutionize how consumer electronics are conceived and produced, paving the way for a plethora of innovative devices that seamlessly blend form and function.

Why Printable Circuit Boards are Revolutionizing Modern Electronics Design - Innovative Applications of Printable Circuit Boards in Consumer Electronics

| Application | Description | Benefits | Challenges |

|---|---|---|---|

| Wearable Technology | Flexible electronic components integrated into clothing or accessories. | Lightweight, low-cost, and customizable designs. | Durability and water resistance issues. |

| Smart Packaging | Integration of sensors and electronics in packaging materials. | Improved consumer interaction and product tracking. | Regulatory approvals and production costs. |

| Medical Devices | Printed sensors for monitoring patient health. | Compact size and ease of integration into existing systems. | Precision and reliability concerns. |

| IoT Devices | Printed circuits in devices that connect to the internet. | Lower manufacturing costs and scalability. | Security vulnerabilities and standardization issues. |

Environmental Impact: Sustainability of Printable Circuit Board Technology

The emergence of printable circuit board (PCB) technology is not just a leap forward in electronics design but also a significant move towards sustainability. Traditional PCBs often rely on toxic materials and complex manufacturing processes that generate substantial waste and environmental degradation. In contrast, printable PCBs utilize eco-friendly inks and materials, which drastically reduce harmful by-products. This innovation allows for a more efficient production cycle, minimizing waste during manufacturing and enabling a streamlined process that is both cost-effective and less harmful to the planet.

Moreover, the adaptability of printable circuit board technology fosters recycling and reusability. As the electronics industry shifts toward more modular designs, printable PCBs can easily be integrated into various applications, making them ideal for short-lived devices prevalent in today's fast-paced tech landscape. The potential to create biodegradable electronics further enhances their environmental profile, ensuring that products have a lesser impact on landfills and ecosystems. This blend of functionality and sustainability positions printable circuit boards as a crucial element in advancing a greener future for electronics.

Environmental Impact: Sustainability of Printable Circuit Board Technology

Related Posts

-

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

Top 10 Printed PCB Board Insights: Trends, Market Value & Manufacturing Innovations in 2023

-

10 Essential Tips for Designing High-Quality PCB Flex Circuits

-

Why Understanding PCB Production is Essential for Modern Electronics

-

The Future of Electronics: How Flexible Printed Circuit Boards are Revolutionizing Device Design