Why Printed Circuit Boards Are Essential for Modern Electronics Development

In the rapidly evolving landscape of modern electronics, printed circuit boards (PCBs) have become an indispensable component in numerous applications, from consumer gadgets to advanced aerospace technology. The global PCB market is projected to reach approximately $75 billion by 2025, driven by the increasing demand for electronic devices and the miniaturization of components. As innovation accelerates in sectors such as automotive electronics and the Internet of Things (IoT), it is essential to understand the pivotal role that printed circuit boards play in facilitating both design and functionality.

According to Dr. Emily Chen, a leading expert in PCB technology, "The quality and complexity of printed circuit boards directly influence the performance and longevity of electronic devices." Her insights underscore the importance of investing in advanced PCB manufacturing techniques to ensure that devices can handle the demands of next-generation technology. As we explore the essential nature of PCBs in modern electronics development, it becomes clear that maintaining high-quality standards in their production is critical for driving innovation and ensuring the reliability of future electronic systems.

The Crucial Role of Printed Circuit Boards in Current Electronic Innovations

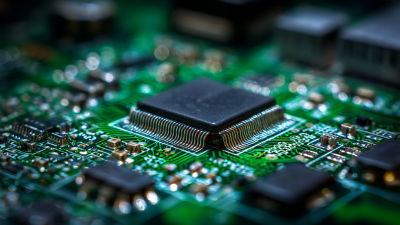

Printed circuit boards (PCBs) are at the forefront of modern electronic innovations, serving as the backbone for diverse applications ranging from consumer electronics to advanced aerospace systems. Their essential role lies in creating a reliable foundation for electrical connections, enabling the miniaturization and integration of complex components. As technology evolves, the demand for higher precision in PCB design and manufacturing has surged, driving innovations in materials and fabrication techniques that cater to the needs of next-generation devices.

One significant trend shaping the future of electronics manufacturing is the rise of 3D-printed electronics. This emerging technology allows for the creation of intricate circuit designs directly onto various substrates, enhancing customization and reducing production times. As the market for 3D-printed electronics is projected to reach substantial growth by 2026, it presents new opportunities for engineers and designers to innovate. This shift also highlights the critical role of PCBs, which will continue to adapt and evolve in conjunction with these advancements, ensuring that they remain integral to the progress of electronic technologies.

Why Printed Circuit Boards Are Essential for Modern Electronics Development

| Application | Type of PCB | Material Used | Manufacturing Technique | Key Features |

|---|---|---|---|---|

| Consumer Electronics | Single-Sided PCB | FR-4 | Etching | Cost-effective, easy to manufacture |

| Telecommunications | Double-Sided PCB | CEM-1 | Via Plating | High-density interconnections |

| Automotive | Multilayer PCB | Polyimide | Laser Drilling | High thermal resistance |

| Medical Devices | Flexible PCB | Polyester | Screen Printing | Compact design, lightweight |

| Aerospace | Rigid-Flex PCB | Teflon | High-frequency Lamination | Durability and flexibility under harsh conditions |

Key Features That Make PCBs Indispensable in Modern Devices

Printed Circuit Boards (PCBs) serve as the backbone of modern electronics, integral to the operation of various devices from smartphones to medical equipment. One of the key features that make PCBs indispensable is their ability to compactly integrate numerous components while maintaining reliability and performance. According to the IPC, an international trade association for the electronics industry, the global PCB market was valued at approximately $62 billion in 2020 and is projected to reach $80 billion by 2025, underscoring the increasing demand for optimized circuit designs that facilitate miniaturization without compromising functionality.

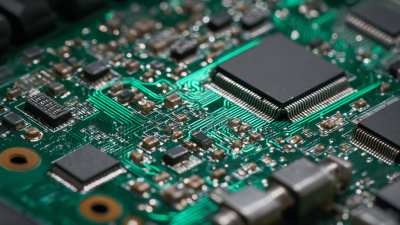

Moreover, the functionality of PCBs is enhanced by advanced fabrication technologies. Multi-layer PCBs, for instance, allow for complex circuitry with high-density interconnections, which are essential for high-performance computing and telecommunications. A report by Research and Markets indicates that the market for multi-layer PCBs alone is anticipated to grow at a CAGR of around 8.5% from 2021 to 2026. Additionally, the shift towards automation and smart technology further emphasizes the need for PCBs that can support IoT devices, enabling seamless communication and data transfer in an interconnected environment. This evolution highlights the critical role of PCBs in the ongoing advancement of modern electronics.

Importance of Key Features of Printed Circuit Boards (PCBs) in Electronics Development

This chart illustrates the significance of various key features of printed circuit boards in modern electronic devices. As electronics evolve, these features play a crucial role in performance and reliability.

Emerging Trends in PCB Technology for Future Electronics

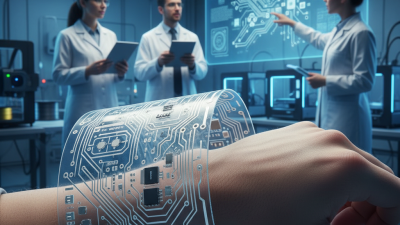

Emerging trends in PCB technology are driving significant advancements in the electronics industry. With the continuous push for miniaturization and enhanced performance, the integration of flexible PCBs and high-density interconnects has become crucial. These technologies not only reduce the size of devices but also improve their functionality, paving the way for innovative applications in sectors like IoT, automotive, and healthcare.

As startups flood the market with groundbreaking solutions, businesses must stay informed to remain competitive. Among the top trends reshaping electronics manufacturing are smart PCBs that utilize sensors for real-time data collection and adaptive functionalities. Additionally, the rise of sustainable materials and processes is gaining momentum, reflecting a shift towards environmental consciousness in production.

Tip: To stay ahead in the industry, companies should consider partnerships with emerging startups that specialize in advanced PCB technologies. Investing in research and development for innovative materials can also ensure that your products meet evolving consumer demands and regulatory standards. Keeping abreast of these trends will not only enhance your product offerings but also position your business for future growth.

Challenges and Solutions in PCB Manufacturing and Design

Printed circuit boards (PCBs) are the backbone of modern electronics, yet their manufacturing and design present unique challenges. According to a report by IPC (Association Connecting Electronics Industries), over 80% of electronics design engineers struggle with high costs and extended lead times in PCB production. As technology advances, the demand for more complex PCB designs increases, leading to difficulties such as signal integrity issues and thermal management. These challenges require innovative solutions, including the adoption of advanced materials and automation in manufacturing processes.

To tackle these issues effectively, engineers should consider adopting simulation tools during the design phase. This can help predict potential problems before moving to production. Additionally, collaborating closely with manufacturers can help ensure that design specifications are met while adhering to budget constraints.

Tip: Always conduct a thorough design review before finalizing a PCB to catch errors early and save costs later. Implementing modular designs can also enhance flexibility and make future upgrades more manageable. As the industry continues to evolve, staying informed about the latest trends and technologies will be crucial for successful PCB development.

The Future of Electronics: The Impact of Advanced PCB Designs on Industry发展

The future of electronics development is closely tied to the advancement of printed circuit board (PCB) designs. As industries evolve, cutting-edge PCB technologies are essential in driving innovation across various sectors, particularly in automotive and consumer electronics. The global automotive PCB market is expected to grow from $9.15 billion in 2023 to $15.1 billion by 2032, showcasing a compound annual growth rate (CAGR) of 5.9%. This growth reflects the increasing complexity and functionality of vehicles, where enhanced PCBs are vital for integrating advanced systems that support electric and autonomous vehicles.

Advancements in PCB design not only streamline manufacturing processes but also enhance performance, leading to the emergence of sophisticated applications like high-speed chips and intelligent sensors used in smart homes. As electronic devices become more interconnected, the demand for efficient, versatile PCB designs will rise.

**Tips:** When considering PCB designs, prioritize materials that offer durability and thermal management. Additionally, staying abreast of market trends can provide insights into emerging technologies that may require innovative PCB solutions to remain competitive. Collaborating with industry experts during the design phase can also yield valuable perspectives that help shape long-term strategies.

Related Posts

-

How Printed Circuit Boards Shape the Future of Technology with Insights from Industry Trends

-

Why Understanding PCB Production is Essential for Modern Electronics

-

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

Why Printable Circuit Boards are Revolutionizing Modern Electronics Design

-

Understanding the Essential Role of Printed PCBs in Modern Electronics