Top Circuit Boards Technologies Transforming Electronics Today?

The evolution of circuit boards has reshaped the electronics landscape. These essential components serve as the foundation of modern devices. They connect various electronic elements, facilitating communication and functionality. Today, circuit boards are becoming smarter and more sophisticated, pushing the boundaries of technology.

Recent advancements enhance their capabilities and performance. Flexible circuit boards, for example, allow for designs that fit various shapes and sizes. This innovation opens up new possibilities for wearables and compact gadgets. However, these progressions come with challenges. The complexity of manufacturing and design can lead to increased costs and production times.

Moreover, sustainability is a pressing issue. The electronics industry faces scrutiny over waste and recyclability. Many circuit boards contain materials harmful to the environment. This raises the question: how can we innovate while remaining responsible? As we explore these transformative circuit board technologies, we must also reflect on their impact. Balancing progress with sustainability is vital for the future of electronics.

Emerging Trends in Circuit Board Technologies Shaping Electronics Landscape

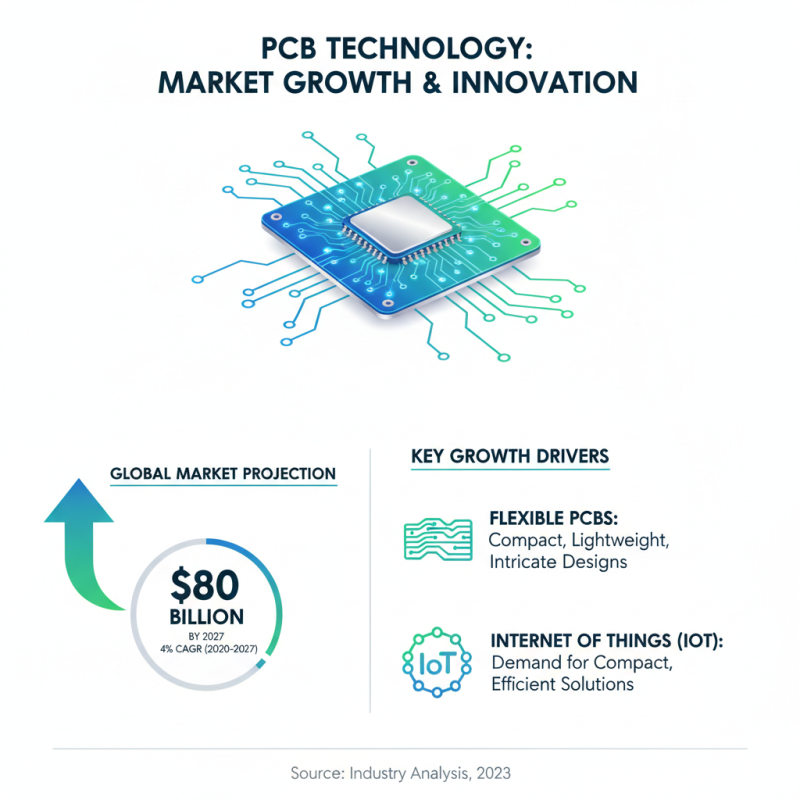

In today's rapidly evolving electronics sector, circuit board technology plays a pivotal role. The global market for printed circuit boards (PCBs) is projected to reach $80 billion by 2027, reflecting a compound annual growth rate (CAGR) of over 4% from 2020. This growth stems from innovations like flexible PCBs, enabling intricate designs with reduced space and weight. The rise of the Internet of Things (IoT) has also driven the demand for more compact, efficient circuit solutions.

Emerging trends in circuit board technology include the use of high-density interconnect (HDI) PCBs. These boards cater to the increasing demand for miniaturization in electronic devices. According to recent research, HDI PCBs can improve signal transmission and reduce energy consumption. However, the complexity of manufacturing HDI boards can lead to higher production costs, which may hinder some manufacturers.

Sustainability is another concern. The push for eco-friendly materials in circuit boards is gaining traction. Companies are exploring options like biodegradable substrates. Yet, the trade-off between sustainability and performance is a topic of debate. As the industry moves forward, balancing these factors will be critical for innovation.

Advancements in Flexible and Rigid-Flex Circuit Board Applications

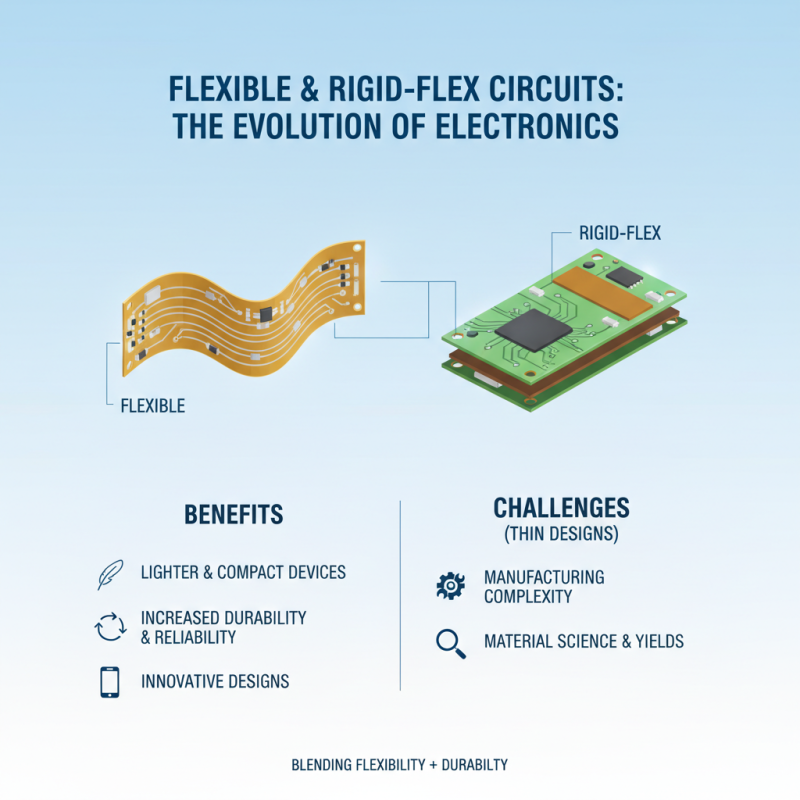

Flexible and rigid-flex circuit boards are changing the landscape of electronics. These boards blend flexibility with durability. They allow devices to become lighter and more compact. Often, manufacturers aim for thinner designs. However, achieving this can be quite challenging.

In wearable technology, flexible circuit boards play a crucial role. They can easily conform to the shapes of the human body. This adaptability enhances comfort and usability. Rigid-flex boards are now favored in smartphones and medical devices. They enable complex designs that meet evolving consumer demands. Yet, the integration process is not seamless. It requires precise engineering and meticulous quality checks.

Environmental concerns also arise with these technologies. Production methods need careful consideration. The recycling of materials is often overlooked. Manufacturers face pressure to innovate while being responsible. Balancing innovation and sustainability remains a major challenge today. It's a fine line between progress and impact. This opens the floor for further exploration and improvement.

Impact of High-Density Interconnect (HDI) Technology on PCB Performance

High-Density Interconnect (HDI) technology is changing how circuit boards perform. This innovation allows for more connections in a smaller area. As devices become smaller and more complex, HDI jackets meet the demand. They can accommodate finer traces and pads. This results in reduced signal loss. However, HDI technology is not without challenges. Fabrication costs can rise, and manufacturing requires precise processes.

Using HDI can lead to more efficient designs. There are fewer layers than traditional PCBs. This makes it easier to create compact devices. The space-saving benefits are significant in mobile and wearable tech. Customers often demand thinner gadgets, pushing engineers to innovate. Yet, the learning curve can be steep. Not all engineers are familiar with HDI techniques. This can lead to mistakes in the design phase.

In real-world applications, HDI technology allows for better thermal management. Heat distribution becomes more effective, resulting in improved longevity of devices. Despite the advantages, some manufacturers hesitate to adopt HDI. A lack of understanding can slow down implementation. These factors highlight the need for ongoing education in the field. Embracing HDI technology is crucial for future advancements. However, it requires careful consideration and preparation.

Impact of High-Density Interconnect (HDI) Technology on PCB Performance

Integration of IoT and Smart Features in Modern Circuit Board Designs

Modern circuit board designs are increasingly focused on integrating IoT and smart features. This trend is reshaping electronics. With a growing reliance on connected devices, engineers are facing new challenges. They must create boards that accommodate more sensors and communication chips.

IoT integration allows for smarter functionalities. For example, boards can now support real-time data processing. This means devices can respond instantly to user inputs. Yet, this complexity can lead to issues such as overheating. Designers must carefully consider heat dissipation methods. Small form factors can complicate these challenges further.

Additionally, the demand for efficiency pushes the boundaries of PCB manufacturing. New materials are being explored to improve durability and performance. However, these innovations are not without their drawbacks. Some materials may increase production costs or lead to longer lead times. Engineers often have to balance performance and practicality. The path forward remains filled with both exciting possibilities and tough questions.

Sustainability in Circuit Board Manufacturing: Trends and Innovations

Sustainability is becoming crucial in circuit board manufacturing. Many companies are exploring eco-friendly materials. Biodegradable resins and recycled metals show promise. These innovations aim to reduce e-waste. Yet, the transition is not flawless. Some materials may compromise performance. This creates a dilemma.

Another trend is energy-efficient production processes. Manufacturers are investing in cleaner energy sources. However, the upfront cost can be a barrier. Smaller firms especially struggle with this transition. Despite challenges, these shifts show a growing commitment to the environment.

Life cycle assessments are also gaining traction. They help companies understand the impact of their products. Yet, implementing these assessments can be complex. Data availability is often limited. This is an area that requires ongoing improvement. Balancing sustainability with performance is an ongoing challenge in the industry.

Top Circuit Boards Technologies Transforming Electronics Today - Sustainability in Circuit Board Manufacturing: Trends and Innovations

| Technology | Description | Sustainability Impact | Key Trends |

|---|---|---|---|

| Flexible Circuit Boards | Thin, lightweight boards that can bend and flex. | Reduces material waste and allows for innovative designs. | Growing use in wearables and IoT devices. |

| Biodegradable PCBs | Boards made from materials that break down naturally. | Minimizes electronic waste in landfills. | Increased adoption in consumer electronics. |

| Nano-coating Technologies | Coatings that enhance durability and functionality. | Reduces need for protective housing materials. | Continuous advancements in material sciences. |

| Recycled PCBs | Boards manufactured from recycled electronic waste. | Addresses resource scarcity and reduces waste. | Increased investments in recycling technologies. |

| High-Density Interconnect (HDI) Boards | Utilizes advanced layer technology for compact designs. | Offers higher performance with lower material use. | Trends towards miniaturization in electronics. |

Related Posts

-

Top 10 Best Printed Circuits Designs for Electronics in 2023

-

Top 10 PC Boards for Optimal Performance in 2023

-

2025 Guide: How to Master PCB Design for Innovative Electronics Projects

-

How Printed Circuit Boards Shape the Future of Technology with Insights from Industry Trends

-

Mastering Circuit Board Design Fundamentals for Beginners in Electrical Engineering

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023