Top 10 PCB Fast Manufacturing Techniques to Improve Efficiency?

In the competitive world of electronics, efficiency is key. PCB fast manufacturing techniques can significantly reduce lead times. According to industry expert Dr. Emily Chen, “Speed doesn't compromise quality; it enhances innovation.”

Many manufacturers overlook the importance of optimizing PCB fast processes. Yet, small changes can lead to big improvements. For example, using automated systems can cut production time. However, some companies rely too heavily on traditional methods. This reliance can slow down progress and limit potential.

Investing in new technology is crucial for growth. A faster production line allows for rapid prototyping. Yet, not all manufacturers are ready to adopt these changes. They must weigh the benefits against the costs. As the industry evolves, the need for ongoing evaluation remains essential. Finding the right balance will make all the difference in achieving true efficiency.

Overview of PCB Manufacturing Techniques

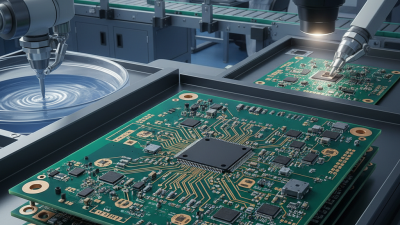

The PCB manufacturing process involves various techniques that greatly affect production efficiency. Recent industry reports indicate that flexible PCBs have grown in usage by 20% in the last three years. This rise reflects a demand for lightweight and compact designs in technology. Additionally, automation in PCB assembly can reduce production time significantly. According to a study, factories using automated assembly lines have reported efficiency improvements of up to 50%.

One notable technique is the use of advanced laser technology for etching. This method ensures precision and speed but is not without challenges. It requires significant upfront investment. Many manufacturers struggle to balance costs with the benefits. Moreover, the trend toward miniaturization complicates matters. Smaller components mean tighter tolerances, leading to increased waste if not managed properly. Implementing new methods without proper training can lead to errors.

Surface-mount technology (SMT) is another method preferred for its speed. SMT can double the board assembly rate when compared to traditional methods. Still, SMT setups can be problematic without regular maintenance, leading to inconsistent product quality. As manufacturers aim for better efficiency, they must address these challenges head-on.

Top 10 PCB Fast Manufacturing Techniques to Improve Efficiency

| Technique | Description | Benefits | Drawbacks |

|---|---|---|---|

| Additive Manufacturing | Layer-by-layer construction of PCBs using printed electronics. | Reduces waste and allows for complex designs. | Slower production speed for large volumes. |

| Rapid Prototyping | Creating quick PCB prototypes using advanced software and equipment. | Speeds up the design validation process. | Can be costly for initial setups. |

| Laser Cutting | Utilizing lasers for precise cutting of PCB materials. | High precision and reduced material waste. | Equipment can be expensive. |

| Vacuum Lamination | Pressing layers together in a vacuum for stronger adhesion. | Improved electrical properties. | Longer setup time. |

| High-Speed Machining | Using CNC machines to mill PCBs efficiently. | Fast turnaround for custom jobs. | Potentially higher cost per unit. |

| Digital Printing | Directly printing circuits onto substrates. | Quick setup and flexibility in design. | Limited material options. |

| Surface Mount Technology | Mounting components directly onto PCB surfaces. | Saves space and improves assembly speed. | Requires precise placement. |

| Automated Optical Inspection (AOI) | Using cameras to inspect PCB quality. | Ensures high-quality production. | Initial setup can be labor-intensive. |

| Thermal Management Techniques | Innovative designs for heat dissipation. | Improves longevity and performance of circuits. | May complicate design process. |

Importance of Efficiency in PCB Production

Efficiency in PCB production is crucial for manufacturers. A recent report by IPC states that efficiency improvements can lead to a 30% reduction in production costs. This reduction significantly impacts the bottom line. As competition intensifies, speed and cost-effectiveness are essential. Traditional methods often slow down production, but modern techniques can change that.

Optimizing production lines can improve output. For instance, using advanced layout software reduces design time by 20%. Additionally, automation plays a key role. Studies show that automated processes can cut assembly time by half. However, implementing such systems is not without challenges. Workers need retraining, and integration can be messy. Despite these drawbacks, the long-term benefits are undeniable.

Furthermore, real-time monitoring of production processes has gained traction. This enables teams to identify bottlenecks promptly. According to a study by Frost & Sullivan, firms utilizing real-time data analytics increased efficiency by up to 25%. However, reliance on technology brings risks. If systems fail, production halts. Balancing technology with human oversight is vital. Increased efficiency can drive success, but it requires careful planning and adaptation.

Top 10 PCB Fast Manufacturing Techniques to Improve Efficiency

Top Fast Manufacturing Techniques for PCBs

When it comes to improving efficiency, adopting fast manufacturing techniques for PCBs is essential. One effective method is using automated processes. Automation reduces human error and speeds up production times. For instance, using pick-and-place machines can quickly assemble components onto the board.

Another technique is the implementation of design for manufacturability (DFM) principles. This approach ensures that designs are optimized for easy assembly. It might mean simplifying layouts or reducing the number of layers. However, it often requires careful consideration and trade-offs. Some designers struggle with balancing complexity and manufacturability.

Additionally, rapid prototyping has gained traction. It allows engineers to test their designs quickly. These prototypes can reveal issues that might not show up in simulations. Yet, this method can lead to oversights if not carefully managed. It’s a reminder that speed should not compromise quality. Ultimately, every technique comes with its own set of challenges and learning moments.

Advantages of Rapid Prototyping in PCB Design

Rapid prototyping is transforming PCB design. It allows for quick iterations and testing of ideas. Designers can produce prototypes in days instead of weeks. This speed is essential in today’s fast-paced market. You'll be able to refine your designs quickly, responding to feedback and challenges.

The benefits of rapid prototyping also include cost savings. Traditional methods can be expensive and time-consuming. By utilizing rapid techniques, teams can reduce waste. They can focus on perfecting their designs. However, the challenge lies in ensuring that prototypes are functional. Sometimes, the speed compromises performance. Iterating too quickly might lead to overlooked details. Balancing speed and quality is key.

Collaboration is another advantage. Rapid prototyping facilitates communication among teams. Engineers and designers can work more closely. They can share ideas and address issues in real-time. However, miscommunication can still happen. It’s vital to have clear channels for feedback. Creating a successful prototype is a learning process that requires reflection.

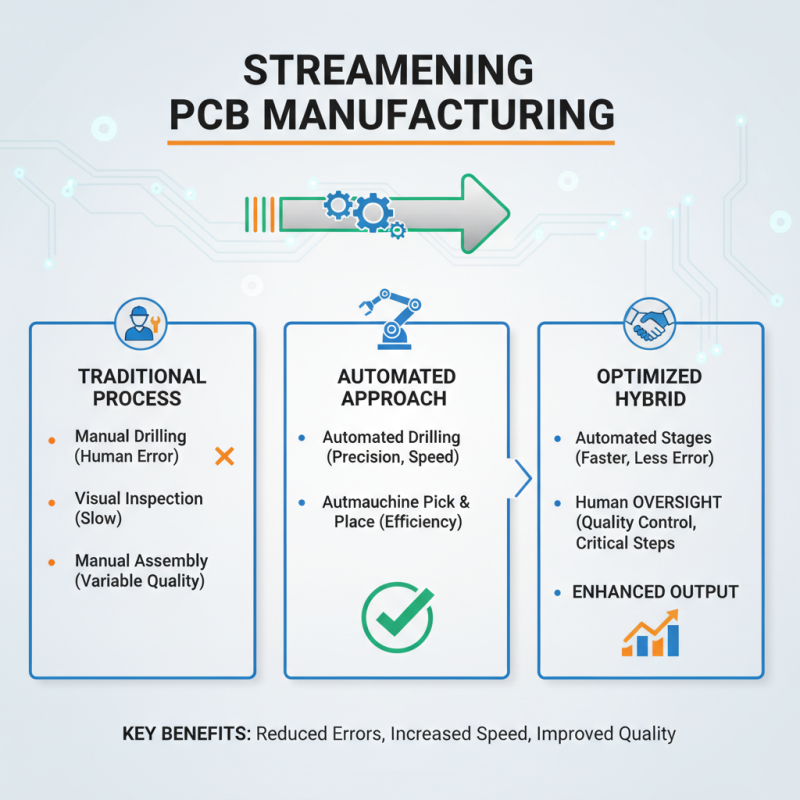

Streamlining Processes for Enhanced PCB Output

Streamlining processes in PCB manufacturing can significantly enhance output. One approach is to automate specific stages. Automation reduces human error and speeds up production. For instance, using machines for drilling can optimize precision. However, relying too much on machines can overlook quality checks. Human oversight is still valuable in critical steps.

Another technique is optimizing layouts for efficient workflow. Organizing workstations reduces movement and idle time. A clear layout streamlines communication among team members. Yet, it's easy to fall into rigid layouts. Flexibility is crucial, allowing teams to adapt as needs change. Regular assessment of workstation efficiency can identify areas for improvement.

Emphasizing continuous training is vital for staff. Regularly scheduled workshops can keep skills sharp. However, some employees may not engage fully in training sessions. Creating a culture of teamwork can encourage participation and knowledge-sharing. It’s essential to find a balance between maintaining speed and ensuring quality. Vigilance in process evaluation can lead to sustained success.

Related Posts

-

Why Understanding PCB Production is Essential for Modern Electronics

-

What is PCB Fabrication and How Does it Impact Your Electronics Projects

-

Top 10 Tips for Efficient PCB Creation: Boost Your Design Skills Today!

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

Why Printed Circuit Boards Are Essential for Modern Electronics Development

-

What is PCB Fabrication The Complete Guide to Understanding PCB Manufacturing