Top PCB Types You Should Know for Effective Electronics Design?

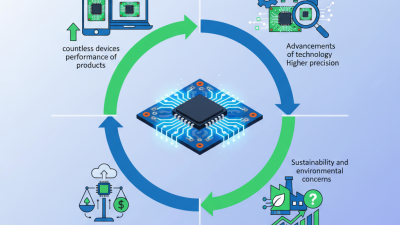

In the world of electronics design, understanding various PCB types is crucial. Different applications demand different designs. According to industry reports, the global PCB market is expected to reach $80 billion by 2026, highlighting its importance.

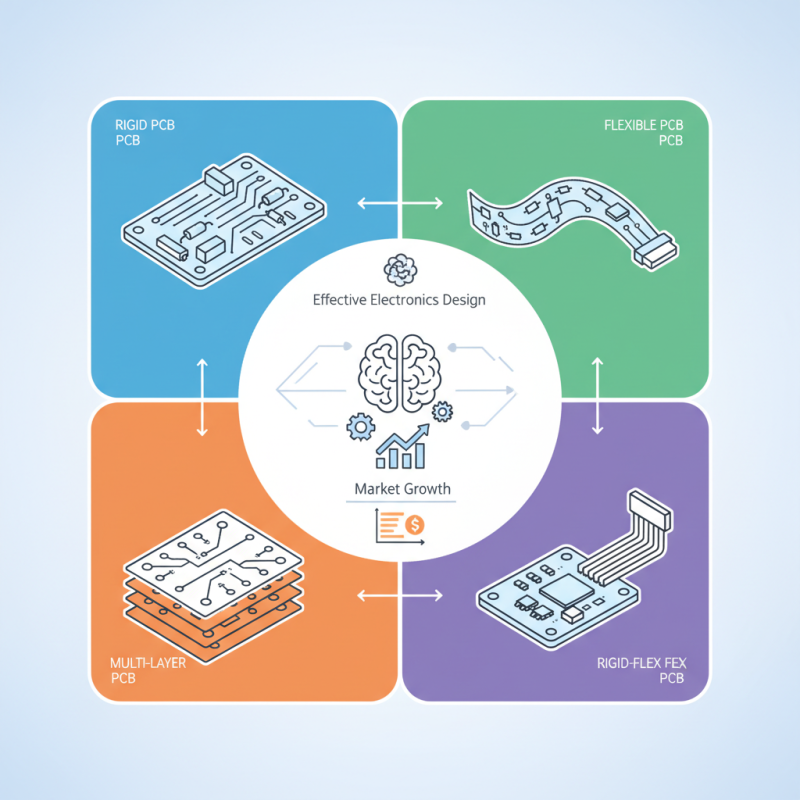

PCBs, or printed circuit boards, come in various types. Each type serves distinct functions. For instance, rigid PCBs are commonly used in consumer electronics. Flexible PCBs, on the other hand, are essential for compact devices. The versatility of these PCB types allows designers to innovate and meet market demands.

However, not all designs are optimal. Many designs overlook necessary considerations, leading to reliability issues. Understanding the characteristics of each PCB type helps avoid these pitfalls. Designers must be aware of their choices and their long-term impact on product performance.

Key Features of Common PCB Types for Electronics Design

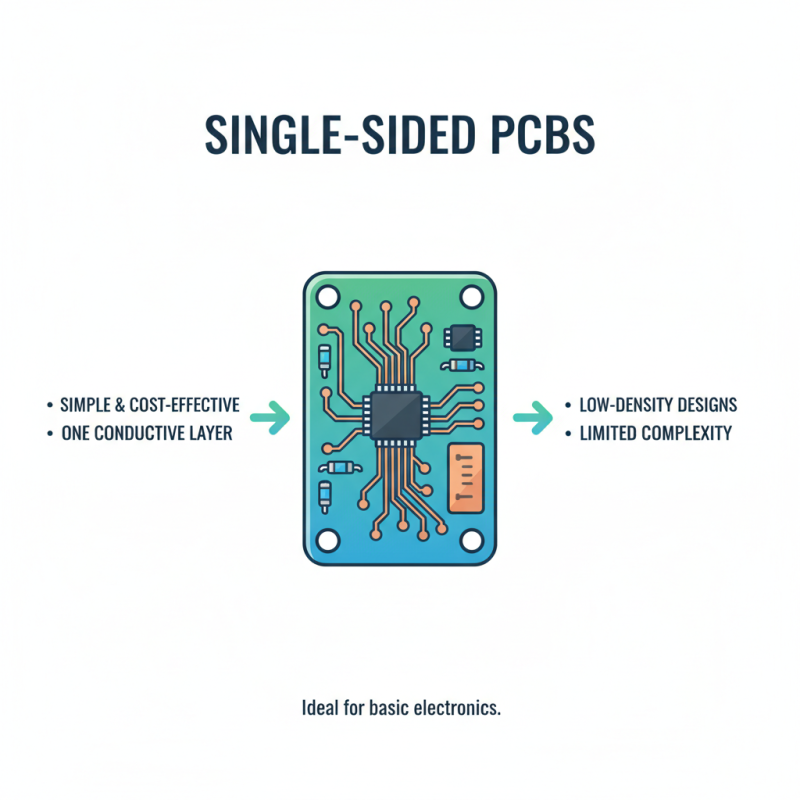

When designing electronics, understanding different PCB types is crucial. Each type has unique features that cater to various applications. For example, single-sided PCBs are simple and cost-effective. They have one layer for components and traces. This makes them suitable for low-density designs. However, they lack the complexity needed for advanced electronics.

Double-sided PCBs are more versatile. They have traces on both sides, allowing for a higher component density. This helps save space in compact devices. But, they require careful placement and soldering techniques. Multi-layer PCBs take this a step further. They contain multiple layers of circuitry. They enable complex designs with high performance. Yet, this complexity can lead to increased manufacturing costs and longer production times.

Rigid PCBs provide durability in fixed applications. They are often used in consumer electronics and industrial devices. Flexible PCBs, on the other hand, can bend and twist. They fit into irregular shapes and are great for portable devices. But, they can be more sensitive to environmental factors. Each type offers distinct advantages and challenges. Knowing these can enhance design efficiency but requires thoughtful consideration.

Comparison of Rigid, Flexible, and Rigid-Flex PCBs

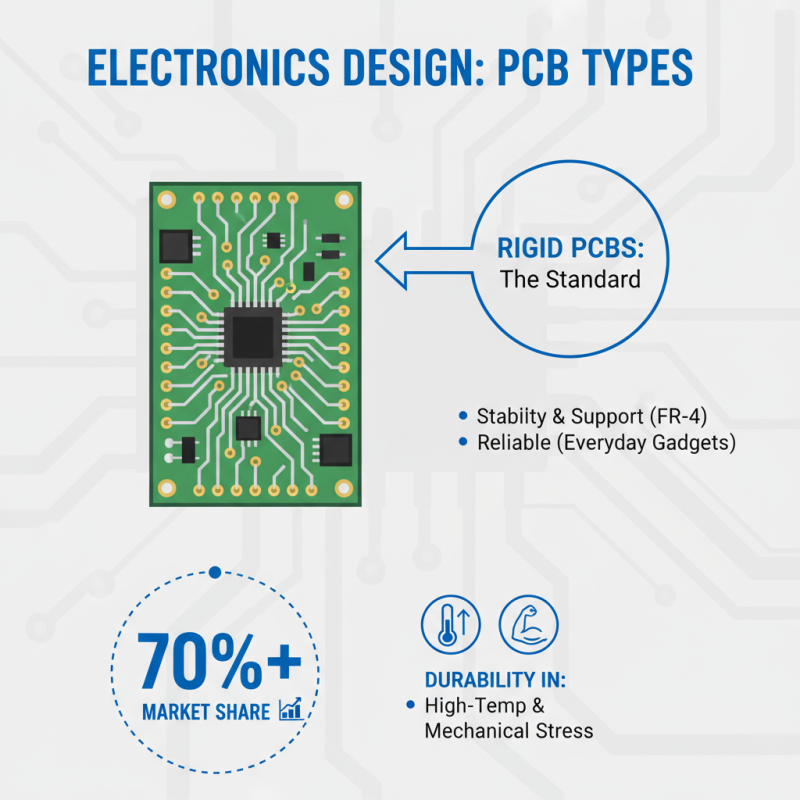

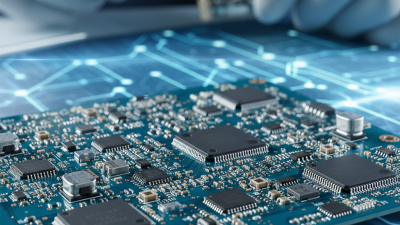

When designing electronics, understanding PCB types is crucial. Rigid PCBs are the most common choice. They provide support and stability. These boards are made from solid materials like FR-4, making them reliable for everyday gadgets. According to a recent industry report, rigid PCBs account for over 70% of the market share. Their durability proves essential in high-temperature environments or applications where mechanical stress occurs.

Flexible PCBs, on the other hand, offer adaptability. They bend and conform to various shapes. This feature is invaluable in compact designs, such as smartphones and wearables. A study shows that the flexible PCB market is expected to grow at a CAGR of 10% from 2023 to 2028. Despite their advantages, flexible boards can present challenges in manufacturing and assembly. These processes often require high precision, which can lead to increased costs if errors occur.

Rigid-flex PCBs combine the best of both worlds. They merge rigid and flexible components into one design. This innovation allows for more complex configurations in compact spaces. However, this complexity can complicate repairs. High manufacturing costs may also deter some designers. Industry experts caution that while these boards are useful, they must be approached with careful consideration of long-term implications on production and logistics.

Applications of Multi-layer PCBs in Advanced Electronics

Multi-layer PCBs play a crucial role in modern electronics. They allow for a compact design while providing necessary functionality. These boards stack multiple layers of circuits. This approach helps save space and reduces weight in many applications. You often find them in smartphones, tablets, and advanced computing devices.

The complexity of multi-layer PCBs can present challenges. Designing them requires meticulous planning. Each layer must be perfectly aligned and connected. Small errors can lead to functional failures. Engineers must carefully consider component placement. This ensures optimal performance and minimizes interference. It's easy to overlook thermal management. Heat can accumulate between layers, affecting reliability.

In industries like aerospace and medical devices, multi-layer PCBs enable critical advancements. They house intricate circuitry that supports high-speed communication and data processing. However, high complexity also means higher risks during manufacturing. A single misstep can compromise the entire board. Engineers must always reflect on their designs to improve reliability. Balancing innovation and practicality remains a constant challenge in electronics design.

Top PCB Types You Should Know for Effective Electronics Design

| PCB Type | Layers | Applications | Advantages |

|---|---|---|---|

| Single-sided PCB | 1 Layer | Basic electronic devices, power supplies | Cost-effective, easy to manufacture |

| Double-sided PCB | 2 Layers | Consumer electronics, automotive | Supports more components, better thermal performance |

| Multi-layer PCB | 3+ Layers | Computers, telecommunications | Compact design, high-density mounting |

| Rigid-flex PCB | Variable | Wearable electronics, medical devices | Flexible design, lightweight |

| High-Frequency PCB | Variable | RF and microwave applications | Optimized for signal integrity, low loss |

Understanding the Manufacturing Process of Various PCB Types

Understanding the manufacturing process of various PCB types is crucial for effective electronics design. Each type of printed circuit board (PCB) has its unique characteristics and manufacturing techniques. For instance, single-sided PCBs are simpler to produce. The process involves applying a copper layer onto a substrate. Then, unwanted copper is etched away. This simplicity makes them cost-effective for many applications.

On the other hand, multi-layer PCBs require more complex processing. They are constructed by stacking multiple layers of materials. Each layer needs precision alignment and bonding. The drilling and plating steps are crucial here. Mistakes in alignment can lead to significant issues later in the product lifecycle. Understanding these nuances is key to avoiding manufacturing flaws.

Rigid and flexible PCBs present their own challenges. Rigid boards may crack under stress if not handled correctly. Flexible boards, while adaptable, require specialized materials. Their manufacturing process can be unpredictable. Designers must be mindful of these factors during the design phase. Reflecting on the manufacturing steps can reveal improvements in both process and design efficiency.

Top PCB Types in Electronics Design

Factors Influencing the Choice of PCB Type in Design Projects

When it comes to PCB design, several factors determine the type you choose. First, consider the intended application. Certain projects need high-frequency performance, demanding specific materials. Others may prioritize cost-effectiveness, opting for standard options. Understanding your end-use will guide your decisions.

Next, assess the complexity of your circuit. More intricate designs often require multilayer PCBs. These can accommodate advanced routing and more components. However, they can be challenging to produce. The design process should reflect a balance between functionality and manufacturability. Simplicity isn’t always the best route; it might lead to a lack of features.

Thermal management and environmental factors are also crucial. High-power applications generate heat. Selecting materials that dissipate heat effectively is vital. Additionally, consider the operating environment. Will the PCB face moisture or extreme temperatures? Addressing these issues early can prevent future problems in your project.

Related Posts

-

2025 Strategies for PCB Prototyping to Improve Product Development Efficiency

-

Top Printable Circuit Board Designs You Need to Know?

-

Top 10 PC Boards for Optimal Performance in 2023

-

Top 10 Benefits of Using Flexible Printed Circuit Boards in Modern Electronics

-

What is PCB Production and How Does it Impact Electronics Industry?

-

Why is Circuit Board Manufacturing Important in Technology?