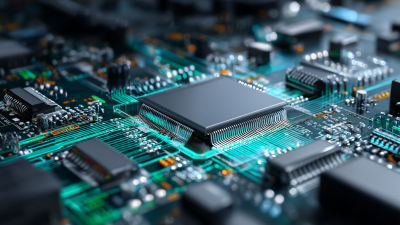

Why Understanding PCB Production is Essential for Modern Electronics

In the rapidly evolving landscape of modern electronics, understanding PCB production is not just a niche interest but a fundamental necessity. Printed Circuit Boards (PCBs) serve as the backbone of virtually every electronic device, from smartphones to sophisticated aerospace systems. With the increasing complexity of electronic designs and the relentless demand for miniaturization, knowledge of PCB production processes has become essential for engineers, designers, and manufacturers alike. This awareness not only ensures the efficiency and reliability of electronic products but also fosters innovation and competitiveness in the industry.

Moreover, as the electronics market expands globally, the intricacies of PCB production—ranging from material selection to manufacturing techniques—play a critical role in determining the quality and performance of final products. The ability to navigate the challenges associated with PCB production can lead to significant cost savings, improved product lifespan, and enhanced functionality. Thus, a comprehensive understanding of PCB production is paramount for stakeholders looking to thrive in the ever-competitive electronics sector. By delving deep into the principles and practices of PCB production, professionals can unlock new potentials in design and innovation, ultimately shaping the future of technology.

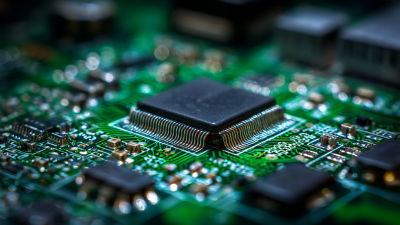

The Significance of PCB Design in Electronics Manufacturing

In the landscape of modern electronics, the design of printed circuit boards (PCBs) is pivotal to the functionality and efficiency of devices. According to a recent report from the IPC Association Connecting Electronics Industries, approximately 80% of electronic product failures can be traced back to PCB design issues. This highlights the critical nature of investing time and resources into meticulous PCB design processes. Optimizing the layout and components on a PCB not only reduces the risk of failure but also enhances the overall performance and cost-effectiveness of the final product.

Tip: When working on PCB design, utilize advanced simulation tools to predict potential issues and enhance design efficiency. Simulations can identify unintentional electromagnetic interference and thermal problems before production, saving both time and costs.

Moreover, the growing complexity of electronic devices necessitates a holistic approach to PCB design. Engineers must consider factors such as signal integrity, power distribution, and manufacturability from the outset. A study by Global Industry Analysts has projected the PCB market to reach $75 billion by 2026, indicating a substantial demand for well-designed and optimized boards. Investing in quality design not only meets industry standards but also positions companies competitively in the fast-evolving electronics market.

Tip: Implement design guidelines established by industry standards, such as IPC-2221, which provides a framework for developing reliable and efficient PCB designs. Following such guidelines can significantly mitigate design risks and improve sustainability in production.

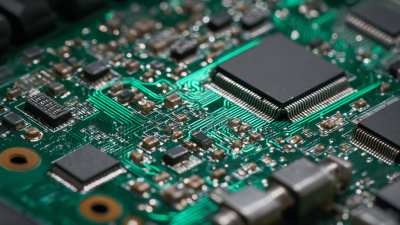

Key Materials Used in PCB Production: An Overview

Understanding the key materials used in PCB production is crucial for navigating the modern electronics landscape. Among these materials, electronic-grade copper oxide stands out as a critical element due to its high purity and performance characteristics, making it indispensable for various applications in electronics, communication, and electrical systems. The demand for this material is expected to grow correspondingly with advancements in sectors like AI computing, new energy vehicles, and 5G technology, underlining its central role in facilitating innovations across these fields.

Furthermore, photoresists are another essential material in PCB production, particularly in the manufacturing of semiconductors and display technologies. Despite the complexities involved in their production, including the substantial R&D investments and time required for technological development, the need for high-quality photoresists continues to surge as the electronics industry evolves. The advancements in PCB technology, driven by these foundational materials, point toward a robust future for electronic manufacturing, highlighting the importance of understanding the materials that underpin this dynamic sector.

Key Materials Used in PCB Production

This chart illustrates the key materials used in the production of printed circuit boards (PCBs) and their respective usage percentages. Copper and FR-4 are the predominant materials, making up a significant portion, while materials such as silver and alumina remain essential yet represent a smaller fraction of the total composition.

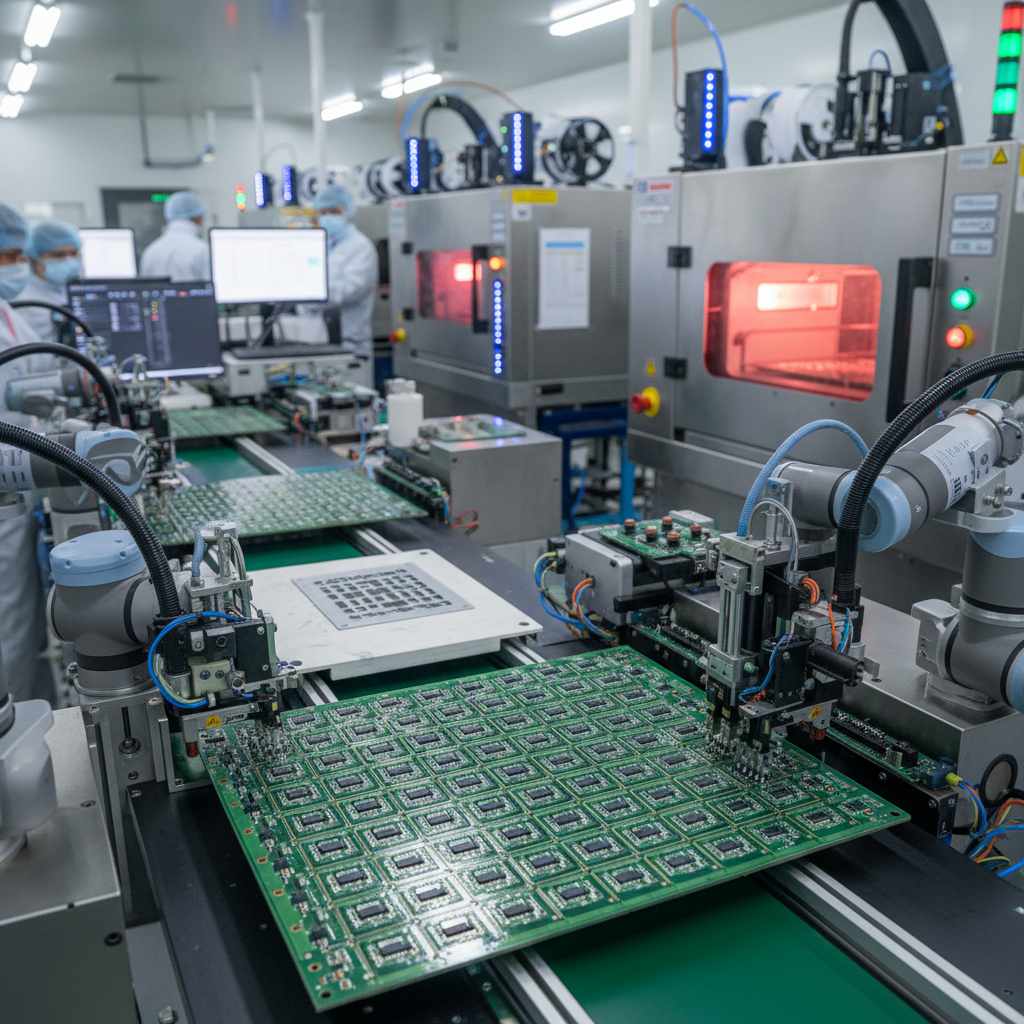

Understanding the PCB Fabrication Process: Steps and Techniques

The printed circuit board (PCB) fabrication process is a crucial component in the electronics manufacturing industry. It involves several meticulous steps, starting from the design and schematic creation to the actual production and assembly of the boards. According to a report by IPC (Institute of Printed Circuits), the global PCB market is projected to reach $80 billion by 2027, underscoring the growing demand for well-fabricated PCBs in various applications, from consumer electronics to advanced medical technologies.

The key steps in the PCB fabrication process include material selection, photolithography, etching, drilling, plating, and surface finishing. Each stage requires meticulous attention to detail and adherence to stringent quality standards. For instance, the IPC-6012 standard outlines the requirements for rigid PCBs and serves as a benchmark for quality assurance.

With advancements in technology, techniques such as automated optical inspection (AOI) are now common, enhancing defect detection rates and ensuring that the final product meets both performance and reliability specifications. As the complexity of electronic devices increases, mastering PCB production techniques becomes vital for manufacturers aiming to stay competitive in the market.

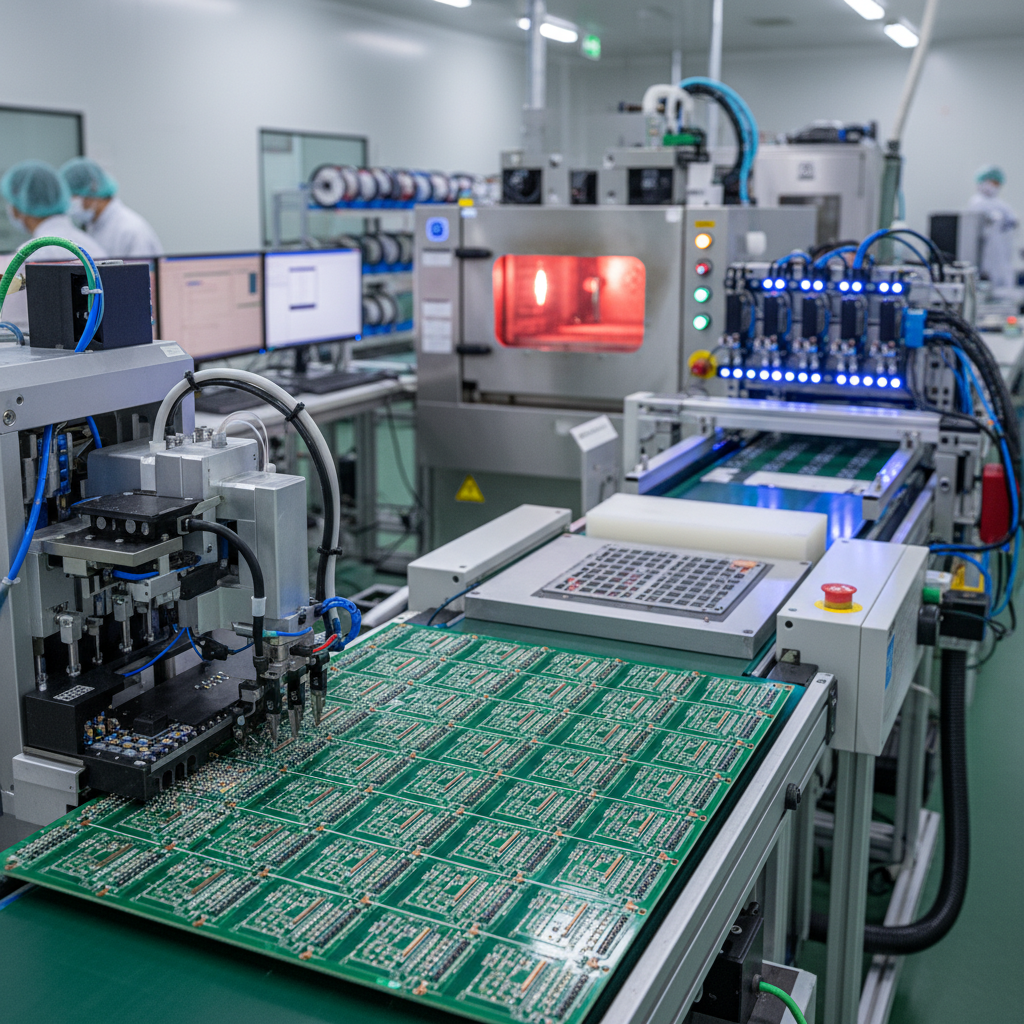

Common Challenges in PCB Production and Their Solutions

Understanding the common challenges in PCB production is crucial for the growth of modern electronics. The global automotive PCB market is projected to grow significantly, increasing from $9.15 billion in 2023 to $15.1 billion by 2032, with a compound annual growth rate (CAGR) of 5.9%. This growth underscores the importance of addressing the production challenges that could hinder progress in this vital sector.

One prominent issue is the complexity of electronic component placement and integrity verification, which can compromise product reliability. In-circuit testing (ICT) has emerged as an effective method for ensuring quality by verifying component placement and solder integrity, making it a crucial tool for manufacturers.

Another challenge arises in the area of PCB depaneling, where offline laser systems are gaining traction. The market for off-line PCB laser depaneling systems is expected to grow from $14.14 million in 2024 to $20.33 million by 2032, reflecting a 4.7% growth rate. These systems address the risks associated with traditional depaneling methods, offering efficiency and precision that are essential as electronic products become increasingly sophisticated. As industry demands evolve, embracing innovative solutions to these challenges will be essential for sustaining growth in the PCB market.

Future Trends in PCB Technology and Their Impact on Electronics

The global automotive PCB market is anticipated to grow significantly, with projections indicating an increase from $9.15 billion in 2023 to $15.1 billion by 2032. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.9%, driven by technological advancements in the automotive sector and a heightened focus on road safety. The overall printed circuit board (PCB) market is also set to expand, expected to surpass $75 billion in 2021, with a growth rate exceeding 5% annually through 2030. This trend underscores the importance of understanding PCB production as it directly influences the evolution of modern electronics.

Emerging trends in PCB technology, such as advanced laser cutting systems and next-generation chip packaging techniques, promise to reshape the electronics landscape. For instance, the offline laser separation system market is projected to reach $203.26 million by 2032, highlighting a growing demand across various applications, including consumer electronics and medical devices. As these innovations continue to evolve, their impact on product design and manufacturing processes will be undeniable, emphasizing the critical nature of staying informed about PCB advancements to harness their full potential in the electronics industry.

Related Posts

-

Top 10 Printed Boards: Best Options for Quality and Performance in 2023

-

Top 10 Benefits of Using Printed PCB Boards for Your Electronics Projects

-

How Printed Circuit Boards Shape the Future of Technology with Insights from Industry Trends

-

Understanding the Essential Role of Printed PCBs in Modern Electronics

-

10 Essential Tips for Designing High-Quality PCB Flex Circuits

-

Mastering Circuit Board Design Fundamentals for Beginners in Electrical Engineering