White Printed Circuit Board: All Pros and Cons

White Printed Circuit board (PCB) form the foundation of virtually every electronic device too. For decades, green solder masks have been the industry standard, protecting copper traces from oxidation, providing insulation, and preventing solder bridges. In recent years, however, white printed circuit board has been gaining popularity. While the solder mask color itself does not change the electrical properties of the circuit, it brings several specific advantages as well as disadvantages that must be considered in design and manufacturing.

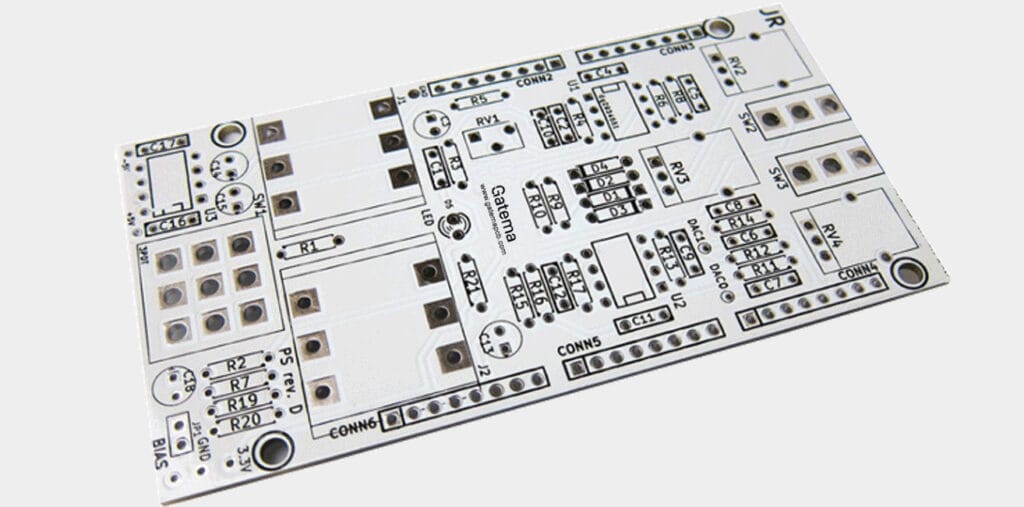

What is a White Printed Circuit Board?

A white PCB is a standard printed circuit board that uses a white solder mask instead of the traditional green. The layer works the same way as on other PCBs – protecting conductive paths, increasing reliability, and simplifying assembly. The difference lies primarily in the optical and visual properties of the white color.

Why Use White Printed Circuit Board?

- High Reflectivity

A white solder mask reflects more than 80% of incident light (green reflects approximately 30–40%). This makes white PCBs ideal for LED lighting, displays, and optoelectronic applications where uniform light distribution and maximum brightness are essential. - Aesthetics and Design

White boards provide a modern and clean look, making them attractive for consumer electronics where design plays a crucial role – such as smartphones, gadgets, or premium televisions. - Better Contrast in white printed circuit board

components, markings, and symbols stand out more clearly on a white background, simplifying inspection, repair, and testing during manufacturing and use. - Specialized Applications

A white substrate is sometimes required for specific purposes – for example, in sensors, scientific detectors, or optical devices, where high reflectivity is necessary for proper operation.

What Are the Disadvantages of White PCBs?

- Higher Cost

White solder masks are more complex to manufacture and require higher-quality materials to resist yellowing and degradation. This usually increases PCB cost by 20–30% compared to standard green boards. - Technical Limitations

- Some white solder masks have lower insulation resistance and dielectric strength.

- They may show reduced adhesion to the substrate, increasing the risk of delamination.

- Poor-quality materials can crack or deform at higher temperatures.

- Sensitivity to Cleanliness

Any dirt, flux residue, or scratches are highly visible on a white surface. Manufacturing and assembly therefore require stricter cleanliness standards and quality control.

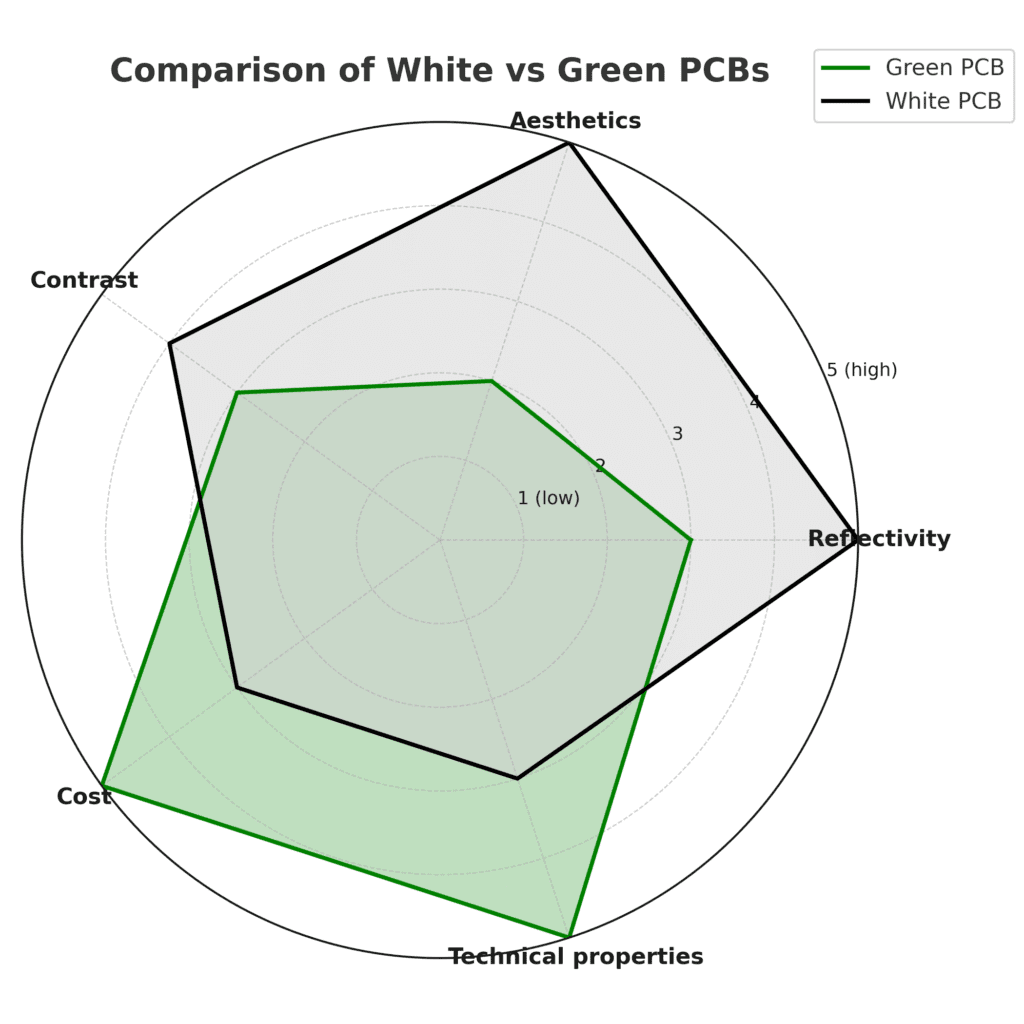

How Do White PCBs Compare with Other Colors?

- White vs. Green: White reflects more light and looks more modern, but is more expensive and may have weaker electrical parameters.

- White vs. Black: Black absorbs light and heats up more, while white reflects it and stays cooler. However, black provides higher contrast for silkscreen printing.

- White vs. Blue: Blue PCBs are priced similarly to white ones and have an industrial look, but are less effective in lighting applications than white.

Where is White Printed Circuit Board Used?

- LED lighting – bulbs, street lamps, architectural and stage lighting.

- Consumer electronics – phones, tablets, gaming systems, smart home devices.

- Medical equipment – surgical tools, imaging systems, diagnostics.

- Telecommunication hardware and 5G infrastructure – antennas, routers, servers.

- Automotive electronics – headlights, infotainment*, LiDAR**, sensors.

- Optoelectronics and scientific instruments – detectors, lab equipment, AR/VR.

* Infotainment: Refers to in-vehicle multimedia systems that combine navigation, radio, music playback, phone connectivity, internet, voice control, and other functions. Typically integrated via touchscreen displays in the dashboard, they serve both driver information and passenger entertainment.

** LiDAR: A laser-based scanning technology. It emits laser beams and measures the time it takes for light to return, creating a 3D map of the surroundings. Widely used in autonomous vehicles (for obstacle detection and distance measurement), as well as in geodesy, robotics, and industrial automation. Often described as a "laser radar," but using light instead of radio waves

Key Considerations When Designing and Manufacturing White Printed Circuit Board

- Choose a high-quality white solder mask with strong reflectivity and resistance to yellowing.

- Use dark, high-contrast silkscreen printing (ideally black) for good readability.

- Verify electrical and insulation properties of the mask for the intended application.

- Conduct adhesion and thermal stability tests.

- Ensure a clean production environment and proper packaging.

- Plan for higher cost and longer lead times compared to standard PCBs.

Conclusion

White printed circuit board is increasingly being adopted in modern electronics. They offer unique optical properties, aesthetics, and contrast, making them ideal for lighting applications, consumer electronics, medical devices, and automotive systems. However, their use requires careful selection of materials and strict manufacturing control. Although they are more expensive than traditional green PCBs, their benefits in many applications clearly outweigh the additional costs.